- Medical & Pharmaceutical industry

- Medical industry

- Semi-automatic filling machine

- Harro Hoefliger Verpackungsmaschinen

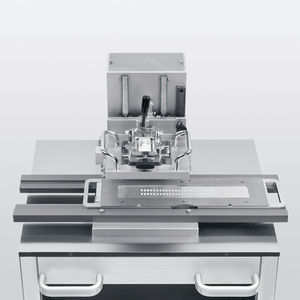

Semi-automatic filling machine SDMAugerpowderfor vials

Add to favorites

Compare this product

Characteristics

- Operational mode

- semi-automatic

- Type

- Auger

- Product applications

- powder

- Container type

- for vials

- Application domain

- for the pharmaceutical industry

- Options

- with capping system

Description

he SDM auger dosing unit fills vials, reservoirs and cartridges with powder. Its purpose is to verify the dosing of the powder and to produce the smallest sample quantities for lab tests. The dosing range can be adjusted variably with servo technology. The SDM can be operated as a standalone unit or as a setup model.

Benefits

Separate drives for stirrer, cross feeding and dosing auger

Tool-free replacement of parts in contact with the powder

Optional tendency regulation based on the “fill-to-weight” principle with gravimetric scale

Optional sterilizable parts in contact with the product

Optional sealing system to prevent the powder from spilling out

Optional integrated ionization of the dust extraction

Technical data

Dosing volume: approx. 20 mm³ – approx. 1000 mm³

Dosing range: 10 – 5000 mg*

Particle size: 1 µm and higher

* At a reference density of the powder of 0.5 mg per mm³

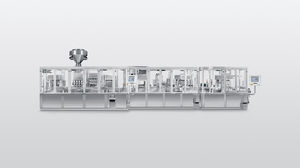

Prepared cavities are placed in the product mounts and transported to the filling station. Minimum quantities of powder are filled at several filling stations within a specific clocking sequence. Dosing units with multiple, synchronized fill positions are used for higher outputs.

Some dry powder inhalers include a powder reservoir for a pre-defined number of dosages. Generally, the defined quantity of active ingredients is filled using an auger filler. Several filling spaces can be integrated to increase the output.

A gravimetric scale calculates the weight during the filling process. Once filling approaches the target weight, the output quantity is reduced and the filling process is continued via fine dosing until the pre-defined target weight is reached exactly.

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsOther Harro Hoefliger Verpackungsmaschinen products

Dosing & filling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.