- Medical & Pharmaceutical industry

- Medical industry

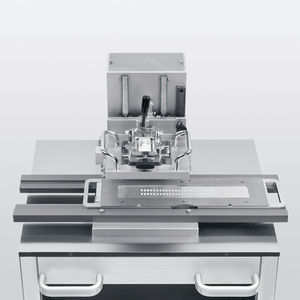

- Compact filling machine

- Harro Hoefliger Verpackungsmaschinen

Compact filling machine Tamping pin TTfor capsulespowderfor the pharmaceutical industry

Add to favorites

Compare this product

Characteristics

- Configuration

- compact

- Product applications

- for capsules, powder

- Application domain

- for the pharmaceutical industry, laboratory

Description

The tamping pin TT is used in the lab during the course of pharmaceutical development or to design dosing formats in production. Even minimum powder quantities (approx. 500 mg or more) are sufficient for testing. With the tamping pin, the fill quantity is dosed using a metering disk. The fill volume depends on the hole and on the height of the disk.

Benefits

Fast determination of product attributes

Precise design of format parts

Binding definition of processes and their parameters

Cost effective production of sample caps

Reproducible, comparable trials

Can be retooled for tamping pins or dosing roller

Technical data

Dosing volume: 50 - 1,385 mm³*

Dosing range: 25 - 690 mg

Particle size: 60 - 150 µm

Remaining quantity: approx. 0 ml

Output: approx. 5 dosages/min.**

* At a reference density of the powder of 0.5 mg per mm³

** Depending on product and operator

Micro-dosing

Various dosing methods allows the dosing of minimal quantities of powder. Depending on the individual powder properties different filling methods such as membrane filling, tamping pin, dosator or drum filling are applicable.

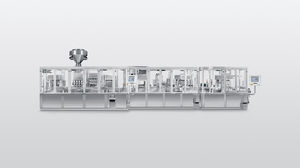

Filling capsules

Various systems for capsule filling allow the dosing of powders, pellets, tablets, mini tablets, powder blends, active ingredients or liquids. It is even possible to dose capsules into capsules.

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsOther Harro Hoefliger Verpackungsmaschinen products

Dosing & filling

Related Searches

- Packaging system for the pharmaceutical industry

- Automatic packaging machine

- Filler for the pharmaceutical industry

- Floor-standing packaging machine

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Film packaging machine

- Medicine packaging system

- Horizontal packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- Table filler

- Vacuum packaging machine

- Automatic cartoning machine

- Intermittent packaging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.