- Medical & Pharmaceutical industry

- Medical industry

- Automatic filling machine

- Harro Hoefliger Verpackungsmaschinen

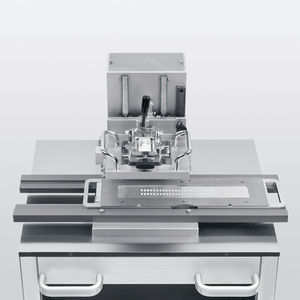

Automated filling machine Disc semi-automaticbenchtoppowder

Add to favorites

Compare this product

Characteristics

- Operational mode

- automated, semi-automatic

- Configuration

- benchtop

- Product applications

- powder

- Container type

- drum

- Application domain

- for the pharmaceutical industry

Description

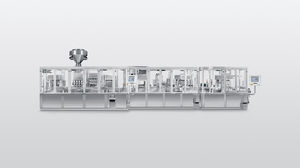

The Disc Filler fills DPI discs with any number or shape of cavities in a single operation. Only exchange two format parts for a quick format or product change at any time. The Disc Filler can be integrated into automated machines to fill, assemble and package disc-base inhalers and increase the output by adding additional filling heads.

Benefits

Fast, simultaneous filling of DPI disc cavities

Easy format and product change

Precise micro-dosing of a variety of powders

Adjustable filling quantity

Gentle powder handling to prevent abrasion and clogging

Suitable for cavities of varying geometries and arrangements

Final products

DPI Discs

Diagnostic applications

Lab automation

Filling discs

Preformed cavities are positioned in the product working fixture. Minimum quantities of powder are filled using a membrane filling method with synchronously working fill positions. This ensures a fast and equal filling for all disc cavities.

Micro-dosing

Various dosing methods allows the dosing of minimal quantities of powder. Depending on the individual powder properties different filling methods such as membrane filling, tamping pin, dosator or drum filling are applicable.

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsOther Harro Hoefliger Verpackungsmaschinen products

Dosing & filling

Related Searches

- Packaging system for the pharmaceutical industry

- Automatic packaging machine

- Filler for the pharmaceutical industry

- Floor-standing packaging machine

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Film packaging machine

- Medicine packaging system

- Horizontal packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- Table filler

- Vacuum packaging machine

- Automatic cartoning machine

- Intermittent packaging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.