- Medical & Pharmaceutical industry

- Medical industry

- Fully-automatic packaging system

- Harro Hoefliger Verpackungsmaschinen

- Products

- Catalogs

- News & Trends

- Exhibitions

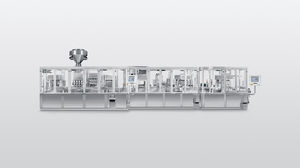

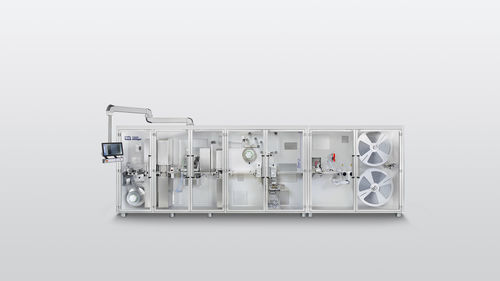

Fully-automatic packaging machine SSP2continuousintermittentform-fill-seal

Add to favorites

Compare this product

Characteristics

- Operational mode

- fully-automatic, intermittent, continuous

- Type

- form-fill-seal

- Product applications

- powder

- Container type

- blister, film, drum

- Options

- sealing

- Production capacity

144 p/min

Description

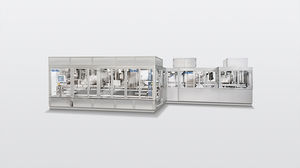

The SSP2 forms, fills and seals blister strips and allows a fully-automatic production. Filling can be done alternately either via drum dosage to partially fill cavities or via membrane dosing for complete filling. The blister packaging can be customized as wound double strips or sheared single strips, mounted by down-stream machines and then finally packaged.

Benefits

Separate production area with good accessibility

Integrable containment for operator protection while processing highly-active and toxic products

Continuous inspection of the product quality

Ease of use and easy maintenance

Compact design with minimal set-up space

Technical data

Membrane dosing: 900 Fill volumes/min (15 cycles/min.)

Web width: 150 mm

Output: up to 11 strips/min (blister strips with 60 cups)

Final products

Aluminum blister strips for inhalers

Periphery

Mounting machine for inhalers

Final packaging machines

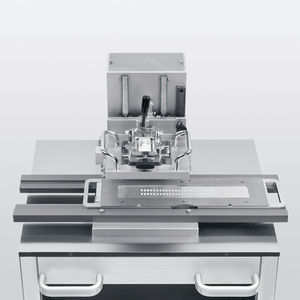

Forming blisters

Minimum quantities of active-ingredient powder are dosed into blister cavities for dry powder inhalers. Plastic forming of these tiny cavities is achieved through thermal forming (PE film) or cold forming (aluminum film).

Filling blisters

The powder filling module can be equipped with a drum filler or with a membrane filler. The drum filler produces partially filled cavities whereas membrane filler is filling the blister cavity to 100%.

Closing blisters

Filled blisters are closed with covering or forming film. The sealing tools used can be configured by adjusting pressure, temperature and time separately for each material.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other Harro Hoefliger Verpackungsmaschinen products

Dosing & filling

Related Searches

- Pharmaceutical product packaging machine

- Automatic packaging machine

- Floor-standing packaging machine

- Filler for the pharmaceutical industry

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- Intermittent packaging machine

- Solids packaging machine

- Automatic cartoning machine

- Table filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.