- Medical & Pharmaceutical industry

- Medical industry

- Intermittent packaging system

- Harro Hoefliger Verpackungsmaschinen

- Products

- Catalogs

- News & Trends

- Exhibitions

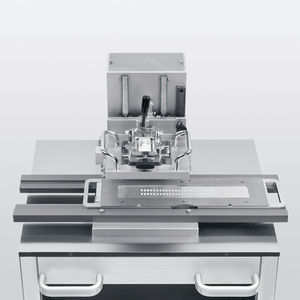

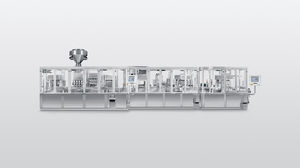

Intermittent packaging machine HSPform-fill-sealblisterfor the pharmaceutical industry

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Operational mode

- intermittent

- Type

- form-fill-seal

- Container type

- blister

- Application domain

- for the pharmaceutical industry

- Other characteristics

- high-speed

- Production capacity

2,520 p/min

Description

The HSP forms, fills and seals up to 2520 blister cups per minute. Six drum filler dosing units are used for filling. Camera inspection systems ensure that the cups are filled and the blister web is sealed. Serial numbers are printed at regular intervals. The blister web is then cut into individual pieces.

Benefits

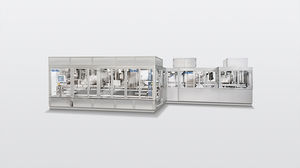

Separate production area with good accessibility

Integrated containment for operator protection when processing highly efficient and toxic products

Reliable inspection systems, in-process inspection of fill quantities

Continuous powder feed with connected containers

Modular construction with minimal setup space

Detection and marking of improperly filled blisters

Technical data

Web width: 200 mm

Output: up to 30 strips/min (blister strips with 60 cups)

Final products

Aluminum blister strips for inhalers

Periphery

Assembly machines

Packaging machines

Micro-dosing

Various dosing methods allows the dosing of minimal quantities of powder. Depending on the individual powder properties different filling methods such as membrane filling, tamping pin, dosator or drum filling are applicable.

Filling blisters

The powder filling module can be equipped with a drum filler or with a membrane filler. The drum filler produces partially filled cavities whereas membrane filler is filling the blister cavity to 100%.

Barrier technology

Compact machine design and detailed knowledge of all processes makes Harro Höfliger a specialist in containment and barrier systems that serve to protect both the operator and the product.For ideal accessibility, ergonomic studies are performed that simulate all processes and operating steps.

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other Harro Hoefliger Verpackungsmaschinen products

Dosing & filling

Related Searches

- Pharmaceutical product packaging machine

- Automatic packaging machine

- Floor-standing packaging machine

- Filler for the pharmaceutical industry

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- Table filler

- Intermittent packaging machine

- Solids packaging machine

- Automatic cartoning machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.