- Medical & Pharmaceutical industry

- Medical industry

- Floor-standing filling machine

- Harro Hoefliger Verpackungsmaschinen

- Products

- Catalogs

- News & Trends

- Exhibitions

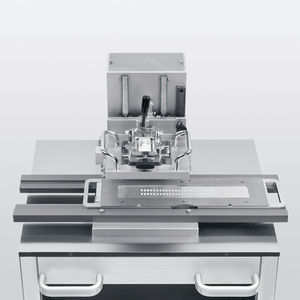

Floor-standing filler FLPfor powdersdrumfor the pharmaceutical industry

Add to favorites

Compare this product

Characteristics

- Configuration

- floor-standing

- Product applications

- for powders

- Container type

- drum

- Application domain

- for the pharmaceutical industry

Description

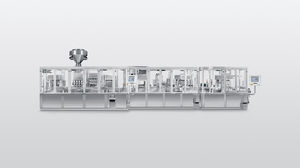

FLP is a production platform for inhaler products. The standard platform makes it possible to easily integrate complex technologies, processes and assembly tasks. This filling machine makes it possible to fill several panels at the same time, while also assembling complex inhalers with unit dose cartridges or multi-dose discs.

Benefits

Standardized platform to integrated technologies and processes

Precise product transport per tray

Ideal for inhaler production with complex dosing, assembly and inspection processes

Easy to link to other technology platforms and packaging machines

Final products

Inhalers with unit dose cartridges

Inhalers with multi-dose discs

Periphery

Tray handling

Packaging machines for shipping boxes

Micro-dosing

Various dosing methods allows the dosing of minimal quantities of powder. Depending on the individual powder properties different filling methods such as membrane filling, tamping pin, dosator or drum filling are applicable.

Device assembly

The assembly processes designed by Harro Höfliger meet simple and complex assembly tasks alike – from inserting reservoirs into inhalers or closing cartridges to the final assembly of DPI inhalers, auto-injectors and pens.

Tray handling

Trays serve to transport sensitive products. Harro Höfliger offers comprehensive solutions to load and unload trays in complete lines, for assembly projects for example. Available systems include a variety of format and performance classes for optimum synchronization.

Final inspection

The final inspection of assembly products is essential for product safety and functional capability.

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other Harro Hoefliger Verpackungsmaschinen products

Dosing & filling

Related Searches

- Pharmaceutical product packaging machine

- Automatic packaging machine

- Floor-standing packaging machine

- Filler for the pharmaceutical industry

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- Intermittent packaging machine

- Solids packaging machine

- Automatic cartoning machine

- Table filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.