- Medical & Pharmaceutical industry

- Medical industry

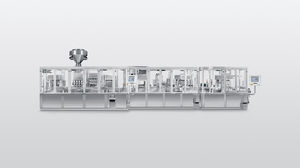

- Liquid filling machine

- Harro Hoefliger Verpackungsmaschinen

Liquid filler Modu-C MSfor capsulespowderfor tablets

Add to favorites

Compare this product

Characteristics

- Product applications

- liquid, for capsules, powder, for tablets

- Application domain

- for the pharmaceutical industry

- Options

- with checkweigher

Description

The Modu-C MS is especially designed for reliable and flexible capsule production. The patented trolley system allows a rapid change of the dosing systems for powder, pellets, tablets, mini tablets and liquid. The machine is impressive with its ease of use and minimum set-up and down times during format changes and cleaning.

Benefits

Flexible with replaceable dosing trolleys

PRP-function (Person reduced production)

Calibration bar to detect deformed capsules, exhaust function of deformed capsules, differential pressure measurement to inspect the presence of capsule bottoms, capsule closure inspection and single elimination of bad capsules.

Minimum set-up time

Easy operation and cleaning

Minimized product loss with No-Cap-No-Fill function

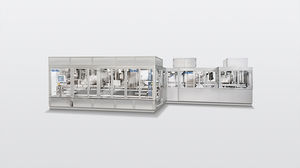

Periphery

Empty capsule feeding (Convey-C)

Customized product feed

In-line and online weight determination: Static gross/net inspection, 100% gross/net inspection, 100% net inspection via capacitive AMV sensor for minimal quantities dosing

Capsule dedusting

Metal detector

Recycling solution for recycling raw materials (RecyCap)

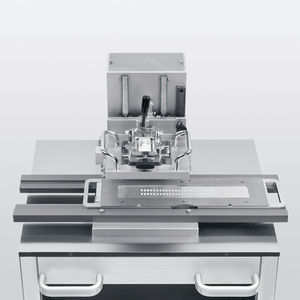

Trolley concept

The patented dosing trolley system allows the operator to quickly change the dosing method: Whether powder, pellets, tablets, mini-tablets or liquid – the next dosing process is already set up. Short setup times, fast cleaning, maximum productivity. Plug-and-play options for the process change.

Capacitive weight inspection

Fastest process analytics through mass acquisition: The mass-specific AMV sensor allows for 100% inspection during the dosing of powders and pellets.The PAT method is independent of the target vessel.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsOther Harro Hoefliger Verpackungsmaschinen products

Dosing & filling

Related Searches

- Pharmaceutical product packaging machine

- Automatic packaging machine

- Floor-standing packaging machine

- Filler for the pharmaceutical industry

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- Table filler

- Intermittent packaging machine

- Automatic cartoning machine

- Solids packaging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.