- Medical & Pharmaceutical industry

- Medical industry

- Intermittent cartoner

- Harro Hoefliger Verpackungsmaschinen

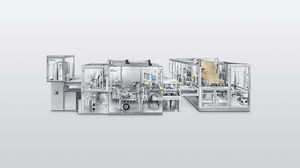

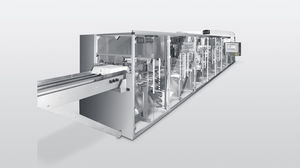

Intermittent cartoner MKTfloor-standingblisterfor vials

Add to favorites

Compare this product

Characteristics

- Operational mode

- intermittent

- Configuration

- floor-standing

- Container type

- blister, for vials

- Application domain

- for the pharmaceutical industry, for the cosmetics industry

- Other characteristics

- modular, high-performance

- Production capacity

100 p/min, 150 p/min

Description

With an output of up to 150 folding cartons per minute, the intermittent MKT offers maximum productivity – and a very small footprint. The quick and easy format change with plug-and-play functionality and an ingenious product transport system make it extremely flexible, so a wide variety of products can be packaged with short setup times. Decentralized servodrive control also ensures that the machine runs quietly and smoothly even at high speeds. The low maintenance requirement increases efficiency further.

Benefits

Modern, robust construction in GMP-appropriate design.

Optimum accessibility

Rapid size changes with reproducible settings

Set-up of all current market folding box closing variants as well as customized closing options

Ability to set up two closing variants on one machine

Highest flexibility with highly dynamic servo drives

Product insertion from the rear (side-loading) ensures a clear machine front and optimal accessibility of the packaging area

Cartoning

Cartoning with our packaging machines features reliable, active opening of folding boxes even for demanding cross-sections, reliable processes when inserting product and package insert, and sophisticated technology for customized folding box closing options.

Product feeding

Product feeding plays a critical role in packaging machines. Harro Höfliger has a large repertoire of product handling systems. The feeding technology is configured individually depending on the requirements of the project and adjusted to the particular specifications.

Brochure

Brochures are folded to the suitable sizes using standardized systems and then inserted into the package.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsOther Harro Hoefliger Verpackungsmaschinen products

Packaging

Related Searches

- Packaging system for the pharmaceutical industry

- Automatic packaging machine

- Floor-standing packaging machine

- Filler for the pharmaceutical industry

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- Automatic cartoning machine

- Intermittent packaging machine

- Table filler

- Vial filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.