- Medical & Pharmaceutical industry

- Medical industry

- Automatic bagging machine

- Harro Hoefliger Verpackungsmaschinen

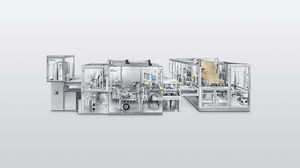

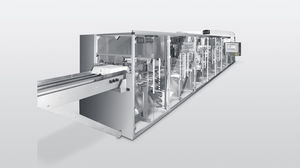

Fully-automatic bagging machine PPHhorizontalin-lineweight

Add to favorites

Compare this product

Characteristics

- Operational mode

- fully-automatic

- Type

- horizontal, in-line, weight, film

- Configuration

- floor-standing

- Product applications

- powder

- Container type

- bag

- Application domain

- for the pharmaceutical industry

- Options

- sealing

- Production capacity

80 p/h, 160 p/h

Description

The pharmaceutical bag machine PPH produces flat bags and fills them with powder and bulk goods. The packaging film is printed in the machine and linearly transported to the three-edge sealing bag for further processing. The bags are delivered in the round motion machine, following by dosing with a 100% weight inspection as well as final sealing. The bags are fed to the downstream cartoning machine via a stacking station and are packaged specifically by format into folding boxes.

Benefits

Modern construction in GMP-appropriate design

Connection to lines and fully automatic production

Separate monitoring of all quality-relevant process steps

Completely protected production room

The ability to manufacture product variants and patient-specific preparations

Integration of micro-dosing systems for bulk goods, powder and liquid

Fast product delivery through parameterized batch release

Periphery

Packaging machines

Labeling systems

Control systems

Bagging

Product packaging in bags plays an important role in product protection and in ensuring sterility. Sophisticated sealing and cutting components guarantee a high performance packaging process – from small to large format applications.

In-line printing

Products can be coded at various positions during the process. Film components or bag webs are printed with a batch code or information about the product quality. Harro Höfliger uses the popular systems thermotransfer, Inkjet or laser.

Sealing

Sealing is one of the central processes when connecting several product layers. We apply several technologies for this process.

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsOther Harro Hoefliger Verpackungsmaschinen products

Packaging

Related Searches

- Packaging system for the pharmaceutical industry

- Automatic packaging machine

- Floor-standing packaging machine

- Filler for the pharmaceutical industry

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- Automatic cartoning machine

- Intermittent packaging machine

- Table filler

- Vial filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.