- Products

- Catalogs

- News & Trends

- Exhibitions

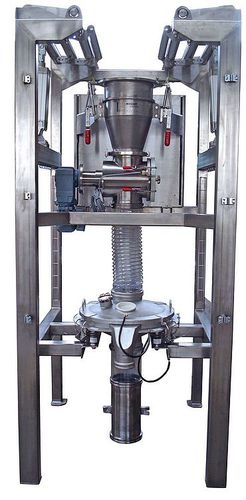

Rotary feeder medical

Add to favorites

Compare this product

Characteristics

- Type

- rotary

- Product applications

- medical

Description

The rotary feeder in easy-to-clean design from HECHT is especially used for frequent product changes. It is a dosing device for various filling stations or loading point for screening machines, particularly for food or pharmaceutical applications. The particularly easy cleaning offers an enormous advantage with frequent product changes.

The rotor is made of synthetic material and therefore very light

Easy dismounting without tools

Various rotorgeometrics and axis

For Ex-zones applicable

Hygienic shaft seal

The single-edged bearing of the rotor makes it easy to dismount the rotor

All surfaces that are in contact with the product are FDA compliant

Easy to clean

The rotor transfers a determined product quantity from the product inlet to the product outlet of the feeder and ensures a controlled and precise dosing. By adjusting the rotational velocity, the product flow can be controlled. A magnetic safety sensor prevents the rotor from driving after the lid is opened.

Related Searches

- Filler for the pharmaceutical industry

- Automatic filler

- Floor-standing filler

- Weight filler

- Container filler

- Continuous-motion filler

- Vertical filler

- Manual filler

- Medical industry filler

- Sealing filler

- Medical conveyor

- Bag filling machine

- Floor-standing conveyor

- Stainless steel conveyor

- Vacuum conveyor

- Pneumatic filling machine

- Powder conveyor

- Drum filling machine

- Vibrating dosing feeder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.