- Laboratory

- Sample management

- Automatic sample preparation system

- Hitachi High-Tech Europe GmbH

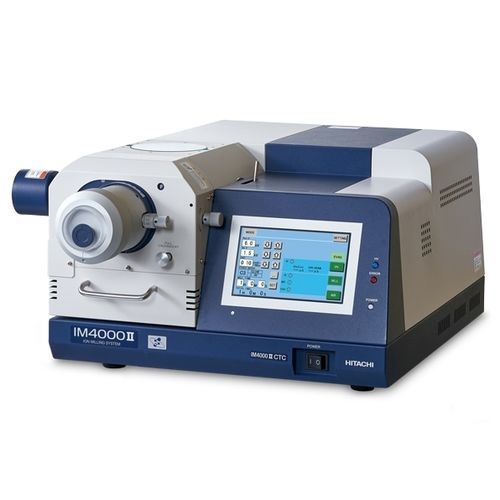

Automatic sample preparation system IM4000 IIfor SEMcoolingion beam milling

Add to favorites

Compare this product

Characteristics

- Operation

- automatic

- Applications

- for SEM

- Preparation type

- cooling, ion beam milling

- Sample type

- surface

- Configuration

- benchtop

Description

IM4000 II is a modular computer-controlled argon ion polishing system that can be equipped as a pure surface polisher, as a cross-section polisher or as a hybrid system, depending on the desired functionality. With a beam energy selectable in 100eV steps from 0.1keV to 6.0keV, a wide range of applications can be covered, from the finest polishes to larger cross-sections. In cross-section operation, IM4000 II achieves a maximum removal rate in Si of 500µm/hour (6keV, protrusion over the mask edge 100µm, stage oscillation ±30°). Functions such as auto-start/time preselection, interval polishing or two-stage processes are available. The IM4000 II-CTC offers the option of process temperatures down to -100°C in cross-section operation.

Product features:

- Single, robust and maintenance-friendly Penning-type ion gun with independent control of beam current and acceleration voltage. Allows intensive ion beams at all acceleration voltages (0-6kV)

- Cross-sectional process depth in Si with 100µm protrusion above mask, stage oscillation +/-30°, is 500µm per hour or more

- Surface polishing can be carried out at tilt angles from 0° to 90°, angle can be changed during the process

- Large sample chamber with a fully retractable multi-axis stage attached to the chamber door to accommodate the various application modules

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Other Hitachi High-Tech Europe GmbH products

Sample Preparation

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.