- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

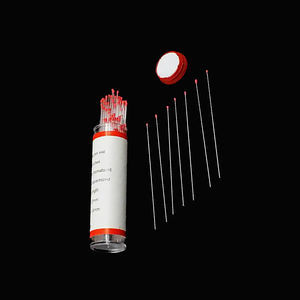

Tube cap for syringesfor vialspush

Add to favorites

Compare this product

Characteristics

- Glassware

- for tubes, for syringes, for vials

- Type

- push

Description

Stoppers and gaskets are vital components in the world of pharmaceuticals, particularly in ensuring the safety and quality of injection liquids and syringes. This article delves into the importance of these sealing solutions, shedding light on their role in maintaining medication safety and preventing contamination. Whether you're an industry professional or simply interested in the pharmaceutical field, join us as we explore how stoppers and gaskets contribute to the safe and efficient delivery of medications through injections.

In the pharmaceutical industry, the safety and quality of medications are paramount. Stoppers and gaskets play a crucial role in achieving these objectives, particularly when it comes to injection liquids and Syringes. This article aims to shed light on the importance of these sealing solutions and their impact on the safety and efficiency of drug administration.

Ensuring Medication Safety:

Stoppers and gaskets act as barriers, preventing any potential contaminants from entering injection liquids or syringes. By providing an airtight seal, they safeguard the integrity of medications, reducing the risk of contamination and ensuring that patients receive safe and effective treatments. Properly sealed injections help prevent the introduction of microorganisms, particles, or other impurities, which can compromise both the drug's efficacy and patients' health.

Preventing Leakage:

Injection liquids and syringes must be tightly sealed to avoid leakage. Stoppers and gaskets play a vital role in preventing any accidental discharge of medication, minimizing wastage, and ensuring accurate dosing.

Catalogs

No catalogs are available for this product.

See all of HWTAi‘s catalogsRelated Searches

- Sample tube

- Container

- Laboratory sample tube

- Microtiter plate

- Collection tube

- Sample box

- Cylindrical collection tube

- Laboratory holder

- 96-well microplate

- Blood collection tube

- Laboratory microplate

- Laboratory vial

- Pipette tip

- Pipette

- Waste container

- Tube laboratory rack

- Polypropylene sample tube

- Sampling kit

- Conical test tube

- Laboratory container

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.