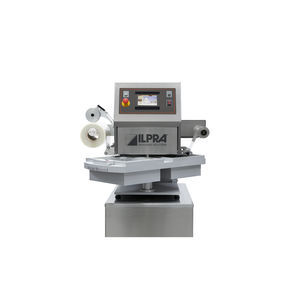

Automatic tray sealer FOODPACK HYPER seriescompact

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Other characteristics

- compact

Description

ILPRA’s Hyper line is the ideal solution for large-scale production needing a reliable, fully mechanical in line tray sealer. With its new CPS (Constant Placement System) technology, the FoodPack Hyper allows continuous infeed of trays, ensuring fast and tireless machine operations that border on perpetual motion. The Hyper is available in 1000 and 1250 versions and can be easily integrated into any production line. This tray sealer also includes advanced features such as the Anti-crush System and ID Control System, which aid in the recognition of authorized personnel. Additionally, the Predictive maintenance system allows for easier planning of overhaul and component replacements. The Hyper line is the perfect solution for food packaging companies seeking a highly efficient and reliable tray sealer that will keep their production running smoothly.

CPS technology

Technology that allows a continuous inflow of trays into the machine. The conveyor belt automatically separates the trays that are transported, without ever stopping, into the sealing mould. To do this, the jaws are electronically interpolated with the conveyor belts.

Anti-crush system

The photocell communicates if a tray is incorrectly positioned, the alarm stops the sealing operation and prevents the tray from being crushed.

Mould Recognition

The FP Hyper software automatically recognises the mould and automatically sets the recipe indicated.

Predictive

The FP Hyper’s PLC monitors each component of the machine and calculates how soon each one will need maintenance or replacement.

TECHNOLOGIES

E-MEC TECHNOLOGY

Based on the fully electromechanical movement of the working station,

VIDEO

Catalogs

No catalogs are available for this product.

See all of Ilpra‘s catalogsRelated Searches

- Automatic packaging machine

- Floor-standing packaging machine

- Sealing packaging machine

- Compact packaging machine

- Film packaging machine

- Continuous packaging machine

- Electronic packing machine

- High-performance packaging machine

- Automatic cartoning machine

- Tray sealer

- Vacuum packaging machine

- Liquid packaging machine

- In-line packaging machine

- Vacuum thermoforming machine

- Vertical packaging machine

- Box packaging machine

- Weight packaging machine

- Palletizer

- Automatic tray sealer

- Medical thermoformer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.