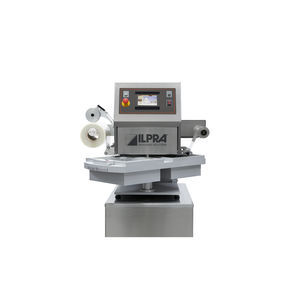

Automatic tray sealer FOODPACK SPEEDY DUOcompact

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Other characteristics

- compact

Description

Speedy Duo is an automatic traysealer configured with two independent sealing units that can be activated via touch screen. In fact, the operator can choose which of the two mould to use and change modes easily and quickly as needed. This eliminates the mould change operation, gaining useful time and increasing productivity.

DETAILS

Large Loading Area

Activated by servo motors and settable via panel to parameterize speed, acceleration and deceleration. An additional option allows a third step to be added, increasing the potential of the load area.

Touch Screen Panel

All working parameters of the machine are controlled by this unit. It stores different recipes for quick use by the operator. The panel includes access to the self-diagnostic system to process and solve any problem of the machine.

Two independent sealing units

It increases productivity by allowing switching from one format to another without the need to change moulds. Should it be necessary, two identical moulds can be processed simultaneously.

Unwinding-rewinding system with automatic reels

This unit has the function of automatically placing the correct amount of heat-sealing film, unwound from a reel, in the sealing area and rewinding the scraps after the sealing-cutting operation.

TECHNOLOGIES

PROGAS SYSTEM

Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed. Available on all models in this line.

Optional: EXTRASKIN SYSTEM

It allows Skin packing even at high degrees of protrusion.

Optional: PRE-HEATING SYSTEM

Pre-heating of the film to optimize packaging in Skin.

Catalogs

No catalogs are available for this product.

See all of Ilpra‘s catalogsRelated Searches

- Automatic packaging machine

- Floor-standing packaging machine

- Sealing packaging machine

- Compact packaging machine

- Film packaging machine

- Continuous packaging machine

- Electronic packing machine

- High-performance packaging machine

- Automatic cartoning machine

- Tray sealer

- Vacuum packaging machine

- Liquid packaging machine

- In-line packaging machine

- Vacuum thermoforming machine

- Vertical packaging machine

- Box packaging machine

- Weight packaging machine

- Palletizer

- Automatic tray sealer

- Medical thermoformer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.