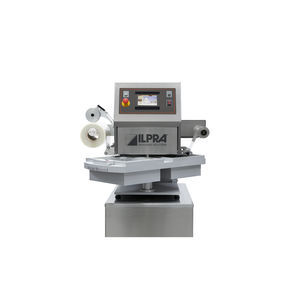

Electronic packaging machine FOODPACK 1450continuousin-linefloor-standing

Add to favorites

Compare this product

Characteristics

- Operational mode

- electronic, continuous

- Type

- in-line

- Configuration

- floor-standing

- Product applications

- conveyor

- Container type

- tray, container, film

- Other characteristics

- high-performance

- Options

- sealing

- Weight

1,500 kg

(3,306.9 lb)- Length

331 cm

(130.31 in)- Width

90 cm

(35.43 in)- Height

190 cm

(74.8 in)

Description

The new Food Pack 1450 is an addition to the existing models of the Linee Food series: it is a fully electronic, elevated efficiency model that combines reliability, versatility and high performance. The development of this model arose from market demand for a high-performance in-line machine that could simultaneously handle three 187×137 mm containers. The design of the machine allows it to be configured to process various packaging applications such as fruit, meat, ready meals, fish and more.

DETAILS

CPS technology

Technology that allows a continuous inflow of trays into the machine. The conveyor belt automatically separates the trays that are transported, without ever stopping, into the sealing mould. To do this, the jaws are electronically interpolated with the conveyor belts.

Constant torque servo drive motors

The movement of the unwinder/rewinder system is guaranteed by two brushless motors: the first is on the unwinding shaft and has the function of unwinding the film according to the quantity set by the control panel. The second brushless motor is on the rewinding shaft and always guarantees the correct film tension in relation to the diameter of the waste reel. These new features allow accurate control of all movement parameters and precision unwinding of the film, both neutral and printed.

Anti-crush system

The photocell communicates if a tray is incorrectly positioned, the alarm stops the sealing operation and prevents the tray from being crushed.

Jaws Carriage

The container transport system is entirely managed by brushless motors. Both the opening and closing movement of the jaws, as well as the longitudinal translation movement,

Catalogs

No catalogs are available for this product.

See all of Ilpra‘s catalogsRelated Searches

- Automatic packaging machine

- Floor-standing packaging machine

- Sealing packaging machine

- Compact packaging machine

- Film packaging machine

- Electronic packing machine

- Continuous packaging machine

- Automatic cartoning machine

- Tray sealer

- High-performance packaging machine

- Vacuum packaging machine

- In-line packaging machine

- Vacuum thermoforming machine

- Liquid packaging machine

- Vertical packaging machine

- Weight packaging machine

- Box packaging machine

- Palletizer

- Automatic tray sealer

- Medical thermoformer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.