- Products

- Catalogs

- News & Trends

- Exhibitions

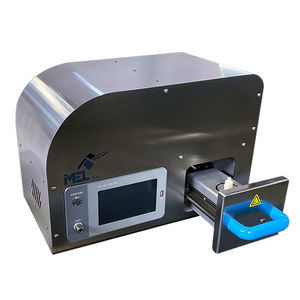

Semi-automatic deblistering machine ECO 50 seriesmanualfor tabletsfor capsules

Add to favorites

Compare this product

Characteristics

- Operational mode

- manual, semi-automatic

- Product applications

- for tablets, for capsules

- Container type

- for cartridges

- Application domain

- for pharmaceutical products, laboratory

Description

IMEL presents the ECO50 serie universal de-blistering machines, capable of de-blistering all types of blisters with quick format changeover and without the use of additional tools.

The machine parts are completely removable and washable.

The machine is manufactured with certified materials, suitable for a direct contact with pharmaceutical and food products.

What makes the ECO50 serie an efficient device is the thought hold in its planning.

The ECO50 serie allows the rescue of blisters with irregularly arranged pockets thanks to the possibility of manual adjustment of the wheels.

IMEL presents different solutions of the ECO50 serie that meet the needs of the customers according to their necessities.

Automated pharmacy dispensing

De-blistering of tablets or capsules from bulk-supplied blisters and refill cartridges from automated dispensing systems.

De-blistering of tablets/capsules from unused packs for valuable clinical trials.

Quality control testing

Testing packaging material characteristics.

Emptying finished blisters which have been rejected from the packaging line because of empty pockets, poor seals, incorrect batch coding etc. The good product can then be re-packaged to increase yield and reduce wastage costs.

Universal semi-automatic de-blistering machine

The machine operates electronically while the blister is inserted manually.

Equipped with protection sensors that detect the closing of the machine and the correct positioning of the recovery trays of the product and the blister.

Both the activation of the machine and the insertion of the blister are manual.

VIDEO

Related Searches

- Pharmaceutical product packaging machine

- Automatic packaging machine

- Sealing packaging machine

- Blister packaging machine

- Leak tester

- Compact packaging machine

- Medicine packaging system

- Pressure leak tester

- Benchtop leak tester

- Leak tester for the pharmaceutical industry

- Sealer for the pharmaceutical industry

- Packaging leak tester

- Capsule packaging machine

- Liquid packaging machine

- Compact leak tester

- Laboratory sealing machine

- USB leak tester

- Manual sealing machine

- Semi-automatic packaging machine

- Vacuum leak tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.