- Dental

- Dental laboratory

- Dental 3D printer

- imes-icore GmbH

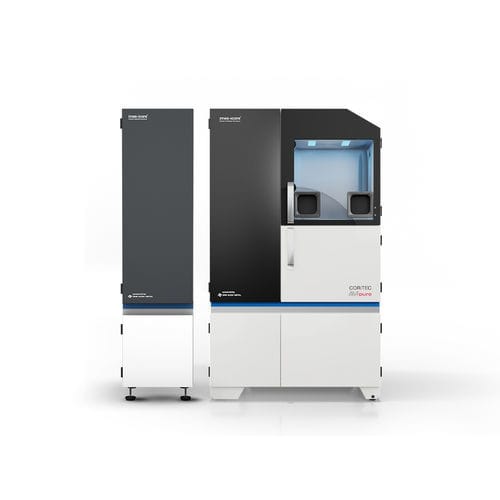

Dental 3D printer CORiTEC® AM 100ultrasonicSLMfloor-standing

Add to favorites

Compare this product

Characteristics

- Applications

- dental

- Technology

- SLM, ultrasonic

- Configuration

- floor-standing

- Other characteristics

- metal

Description

CORiTEC® AM100

Focus on productivity and results

Perfect for milling centres looking for a process to produce complex dental constructions.

Highlights:

- 200 W fibre laser

- Production of complex CoCR and Ti units possible

- Additive manufacturing: Build up layer by layer based on CAD data

- Up to 250 units per processing operation

- Up to 500 units per day

- Fast prototyping

- Integrated powder supply

- Automated and closed powder cycle

- Removable build module

- Intuitive machine operation with CORiTEC® AM100 HMI software

Possible indications:

- Crowns, bridges

- Telescope technique

- Model casting

- Abutments

- Implant prosthetics

Why choose the CORiTEC® AM100?

This modern technology combines speed and sustainability and leads to cost-efficient fabrication of dental restorations.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Dental material

- Restoration dental material

- Analysis software

- PMMA dental material

- Dental prosthesis dental material

- Cupboard with drawer

- Dental crown material

- Dental bridge material

- Medical equipment cabinet

- Biocompatible dental material

- Mobile cabinet

- Wax dental material

- Casting dental material

- Dental software

- Translucent dental material

- Milling dental material

- Design software

- 3D printer

- Orthodontic material

- Zirconium dioxide dental material

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.