- Dental

- Dental laboratory

- CAD/CAM milling machine

- imes-icore GmbH

CAD/CAM milling machine CORiTEC® 650i Loaderdentalfor dental waxfor dental composites

Add to favorites

Compare this product

Characteristics

- Type

- CAD/CAM

- Applications

- dental

- Designed for

- for dental wax, for dental composites, for titanium, for ceramics, for CoCr, for PMMA

- Number of axes

- 5-axis

- Machining type

- dry machining, wet machining

- Configuration

- benchtop

- Spindle speed

50,000 rpm

(314,159 rad.min-1)- Height

1,940 mm

(76.38 in)- Depth

1,100 mm

(43.31 in)- Weight

930 kg

(2,050.3 lb)

Description

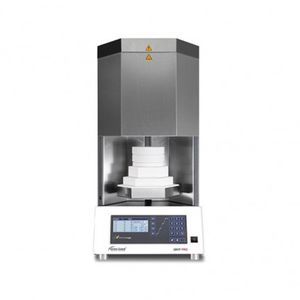

CORiTEC® 650i Loader

Pioneering technology

Perfect for milling centres looking for an automated premium system for special requirements with consistently high precision.

Highlights:

- 5-axis machining

- Hybrid machining possible

- Open system: compatible with all scanners

- Independent: Works autonomously without an external PC

- Processing of all common materials and indications

- Automation and convenience:

- Integrated temperature compensation

- Wet and dry processing possible

- Automatic 16-fold blank changer

- Suitable for 24-hour operation

- Intuitive control via CORiTEC® Remote Dental 3.0

- Integrated touchscreen and HD camera for easy operation and process monitoring

- Water-cooled high-frequency spindle with 3.2 kW output

- Clamping system with HSK 25 tool holder

- 32-position tool changer

- 19 litre integrated coolant tank

Areas of application and possible indications:

Material processing:

- Glass ceramics and lithium disilicate

- zirconium

- Titanium and CoCr abutments

- Sintered metal

- Hybrid materials such as PMMA, PEEK and composite

Indications:

- Telescope technique

- Hybrid processing

- Drill template

- Bar construction

- Superstructure

Why choose the CORiTEC® 650i Loader?

This machine maximises performance while maintaining high precision. It offers processing of all common materials and indications, also suitable for 24-hour operation.

VIDEO

Catalogs

CORiTEC® 650i

17 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Dental material

- Restoration dental material

- Analysis software

- PMMA dental material

- Dental prosthesis dental material

- Cupboard with drawer

- Dental crown material

- Dental bridge material

- Biocompatible dental material

- Medical equipment cabinet

- Mobile cabinet

- Wax dental material

- Casting dental material

- Dental software

- Translucent dental material

- Milling dental material

- Design software

- 3D printer

- Orthodontic material

- Zirconium dioxide dental material

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.