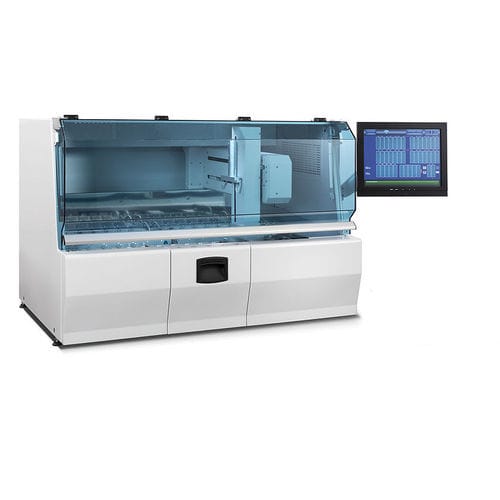

Slide stainer AUS2 automaticfor histologylaboratory

Add to favorites

Compare this product

Characteristics

- Operation

- automatic

- Applications

- laboratory, for slide staining, for histology

- Configuration

- benchtop

Description

Automatic slide stainer with XY translater

Completely programmable

Multi-basket-protocol for histology and citology slide staining

The Intelsint AUS is a modem high throughput XY stainer, specifïcally designed for the operators safety and protection.

A total of 40 stations are available distributed on 3 rows. 28 reagent tanks are allocated in 2 rows (mid and back row), an additional front row contains 5 tanks for flowing

water, 2 input and 3 output tanks on a sliding-drawer with baskets sensors, the remaining 2 positions

of the front row are fitted with warm air slide dryers.

Ail the structural internai parts are made in high quality stainless Steel.

An integrated computer Controls ail opérations and is endowed with a large touch-screen color monitor. The advanced software handles multiple staining protocols

and bath schemes, with a graphie représentation of the work in progress. The HMI is clear and intuitive. Standard keyboard and mouse can be connected for who does not like touch-screen operations.

Slide Dryer Module

The slide stainer can be equipped with a 2-station drying system, each station is provided with a heater and fan. The two units are operated simultaneously so to keep temperature constant.

Temperature is surveyed by means of a probe (thermocouple) placed on the wall situated at the centre of the heater.

Reagent mixing by mechanical up/down movement of the reagent tanks

The slide stainer can be equipped with an agitation system that sways the tanks and reagents contained.

The 28 reagent tanks are allocated in 4 removable racks with 7 tanks for each rack.

VIDEO

Catalogs

Related Searches

- INTELSINT sample preparation system

- INTELSINT automatic sample preparation system

- INTELSINT laboratory sample preparation system

- Benchtop sample processor

- INTELSINT tissue processor

- Histology sample processor

- Slide staining sample processor

- Sample processor with touchscreen

- Modular sample processor

- Floor-standing sample processor

- Fully automated sample processor

- Washing sample processor

- Heating sample processor

- High-speed sample processor

- Drying sample processor

- Sample processor on casters

- Filling sample processor

- Sample preparation system with glass coverslipper

- Cleaning sample preparation system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.