- Medical & Pharmaceutical industry

- Medical industry

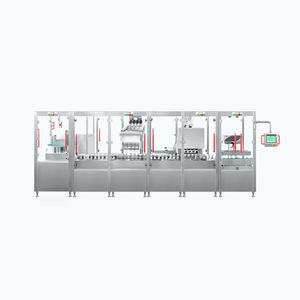

- Servo-driven packaging system

- Jornen Machinery Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Servo-driven packaging system automaticcontinuoushorizontal

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic, continuous, servo-driven

- Type

- horizontal, in-line

- Configuration

- floor-standing

- Product applications

- for tablets, for capsules, solids

- Container type

- bag, bottle, container

- Application domain

- for the pharmaceutical industry, medical industry, for the cosmetics industry, for production, laboratory, for clean rooms, R&D, for industrial applications

- Other characteristics

- high-speed, high-performance

- Options

- sealing, with cartoner module, with touchscreen

- Production capacity

200 p/min

Description

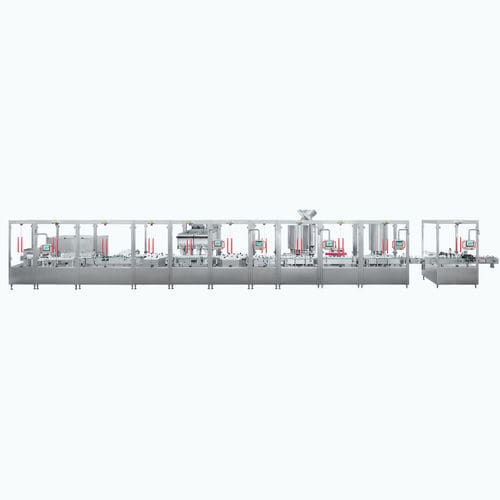

● Fully automated bottle packaging line, including equipment: bottle trimmer, corking machine, granule counting machine and granule counting re-verification system, capping Machine, aluminum foil sealing Machine and sealing leakage in-line detection machine, labeling Machine, etc.

● The production process of the products can meet the requirements of GMP, FDA, and other specifications.

● According to the customer’s actual needs and site conditions, it can meet different capacity requirements and be optional for different equipment combinations to achieve customized services.

● Adoption of compact design improves space-capacity ratio and controls GMP operating costs.

● The combination of a grain counting machine and missing grain detector, the combination of an aluminum foil sealing machine and sealing leakage in-line detector, and other products with detection functions included in the bottle packaging line can reduce the quality risk in the production line and provide users with a more advanced, stable, and reliable bottle packaging line.

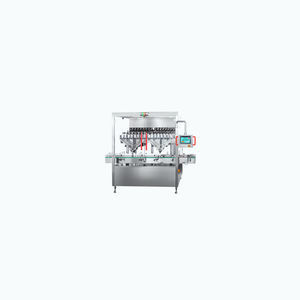

1. Automatic Unscrambler

High speed, high compatibility

Applicable to plastic bottles of all shapes, such as round, square, flat, oval, etc.

Large capacity storage bin

Static electricity and dust-removing functions are available on the Machine.

2. Desiccant Inserter

The precise positioning of the cursor and the checking of the desiccant bag length determination system ensure that the desiccant will not be cut through.

The Machine will alarm and stop if desiccants do not fall into bottles.

The Machine will alarm in time when it runs out of desiccants.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jornen Machinery Co., Ltd‘s catalogsOther Jornen Machinery Co., Ltd products

Solid Dose Bottle Packaging Machines

Related Searches

- Pharmaceutical product packaging machine

- Automatic packaging machine

- Floor-standing packaging machine

- Filler for the pharmaceutical industry

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Continuous packaging machine

- Bag packaging machine

- Electronic packing machine

- Cartoner for the pharmaceutical industry

- High-performance packaging machine

- Intermittent packaging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.