- Medical & Pharmaceutical industry

- Medical industry

- Automatic checkweigher

- Jornen Machinery Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

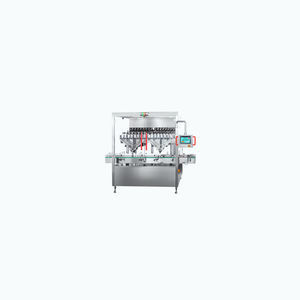

Automatic checkweigher high-speedfor pharmaceutical applications

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic, high-speed

- Applications

- for pharmaceutical applications

Description

During production, the weight of each capsule filled with medicine within the required tolerance would be considered the eligible product. In contrast, the weight of each capsule filled with medicine beyond the required tolerance would be regarded as the eligible product.

Currently, most pharmaceutical factories adopt spot checks to evaluate the accuracy of capsule weight by which the accuracy of each capsule weight cannot be ensured.

Numerous pharmaceutical factories suffer heavy losses yearly because the Medical Regulatory Authorities prove their products ineligible. Therefore, a highly efficient, accurate, and overall checking method is necessary to ensure the accuracy of each capsule’s weight.

This machine, designed to check whether capsule weight is eligible, can automatically weigh each capsule at high speed, with high precision, and without damage. In addition, it can automatically filter and reject the ineligible beyond the required tolerance, separate eligible from ineligible capsules, and collect both in different channels, ensuring each capsule weighs within the required tolerance during the whole manufacturing process.

A micro-weighing sensor system and a Programmable Logic Controller (PLC) with high-speed computing and control were adopted to make the machine steady, reliable, and easy to operate. With the electronic recording function accompanied by an electronic signature, the machine conforms with FDA 21 CFR Part 11.

A Human-Machine interface (HMI) that can set various parameters can automatically trace and record relevant parameters. Meanwhile, using automatic statistics, a touch screen displays the output of eligible and ineligible capsules.

Catalogs

No catalogs are available for this product.

See all of Jornen Machinery Co., Ltd‘s catalogsOther Jornen Machinery Co., Ltd products

Solid Dose Bottle Packaging Machines

Related Searches

- Pharmaceutical product packaging machine

- Automatic packaging machine

- Floor-standing packaging machine

- Filler for the pharmaceutical industry

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Continuous packaging machine

- Bag packaging machine

- Electronic packing machine

- Cartoner for the pharmaceutical industry

- High-performance packaging machine

- Intermittent packaging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.