Automatic compounding system KS-240 for the pharmaceutical industryfor liquid handlingfilling

Add to favorites

Compare this product

Characteristics

- Operation

- automatic

- Applications

- for the pharmaceutical industry

- Preparation type

- filling, for liquid handling

- Configuration

- benchtop

- Other characteristics

- with barcode reader

- Throughput

1,400 p/min

Description

The preparation of complex sterile compounds such as parenteral nutrition is one of the most intricate and error-prone operations in your pharmacy. The KS-240 enhances efficiency and safety in this critical process by providing an ideal workflow through its state-of-the-art features.

General Features

Enhances

Patient Safety

Traceability

Workflow Speed

Quality Assurance

Flexibility

Compliance

ROI

Prevents

Ordering Errors

Compounding Errors

Manual Additions

Touch-Contamination

Drug Loss

Needle-Based Injuries

UV Light Effects

Standart Units

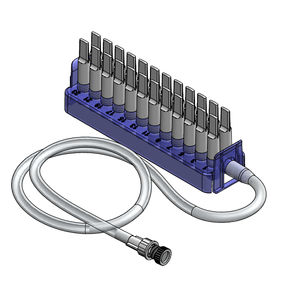

The basic electromechanical unit of the system, consisting of 24-port valve actuators, peristaltic pump mechanism and control system. This unit also includes built-in air bubble and congestion sensors for filling safety.

An embedded industrial-grade PC with a touchscreen, running the KS-240 Device Operating Software, for the automatic filling process.

The gravimetric control unit of the system, which has an integrated load-cell that can be self-calibrated with the calibration weight. Calculates the error ratio of each final product gravimetrically via the information performed by this unit.

Certified 2kg weight that is used for self-calibration of the scale unit.

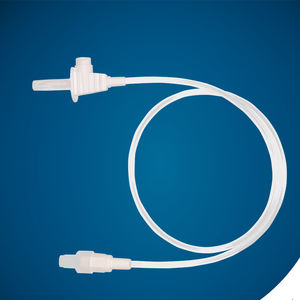

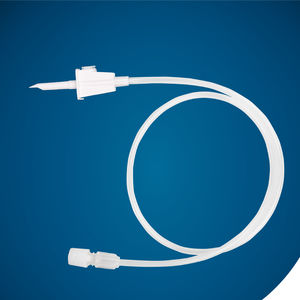

The unit for attaching all the source containers such as bags, bottles, syringes, and vials to the main compounder unit.

The bottom part of the system, which carries the main compounder unit, scale unit, display unit, and rack unit and maintains all these accessories to be assembled stably.

VIDEO

Related Searches

- Laboratory stirrer

- General purpose laboratory stirrer

- Benchtop laboratory stirrer

- Digital laboratory stirrer

- Variable-speed laboratory stirrer

- Compact laboratory stirrer

- Vial laboratory shaker

- Programmable laboratory stirrer

- Multi-position laboratory stirrer

- High-speed laboratory shaker

- Laboratory shaker for the pharmaceutical industry

- Automatic compounding system

- Compounding system

- Compounding system for the pharmaceutical industry

- Multi-function laboratory shaker

- Benchtop compounding system

- Filling compounding system

- Dosing compounding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.