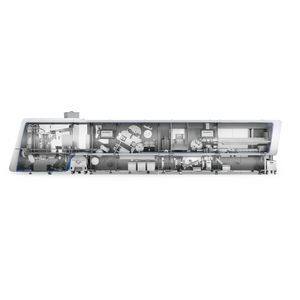

Cartoner for the pharmaceutical industry P1600 automaticfloor-standingmodular

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Configuration

- floor-standing, modular

- Container type

- blister, sachet

- Application domain

- for the pharmaceutical industry

- Other characteristics

- modular, high-performance

- Production capacity

150 p/min, 300 p/min

Description

To ensure that blisters, ampoules, vials and similar reach patients safely and in compliance with GMP, packaging machines for secondary packaging must meet high requirements. The sideload cartoners from Körber are perfectly adapted to this. The flexible, modular machines allow effortless expansion of a blister, sachet or stick pack systems into a complete, high-performance production line.

Process reliability

Digital counting units ensure precise setting during format changes

Time saving

Excellent accessibility enables fast changeovers as well as short non-productive times due to easy and fast cleaning

Flexibility

Teach-in process for different brochure lengths

Well-connected, even for small batch sizes

The flexible cartoning machines P1600 and P3200 are designed for small and medium batch sizes and enable packaging in folding cartons of almost all pharmaceutical products. The integration of additional functions at a later date is no problem thanks to the modular design based on the building block principle. The machines require minimal space and need only a few format parts.

Catalogs

No catalogs are available for this product.

See all of Körber Pharma‘s catalogsRelated Searches

- Körber Pharma packaging system for the pharmaceutical industry

- Körber Pharma automatic packaging system

- Körber Pharma floor-standing packaging system

- Körber Pharma sealing packaging system

- Körber Pharma blister packaging system

- Compact packaging machine

- Körber Pharma medical industry packaging system

- Inspection system for the pharmaceutical industry

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Bag packaging machine

- Automated inspection system

- Körber Pharma cartoner for the pharmaceutical industry

- High-performance packaging machine

- Körber Pharma automatic cartoner

- Solids packaging machine

- Capsule packaging machine

- Körber Pharma floor-standing cartoner

- High-speed packaging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.