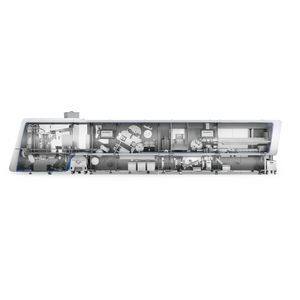

Fully-automatic cartoner NeoTOP Tool seriessemi-automaticfloor-standingmodular

Add to favorites

Compare this product

Characteristics

- Operational mode

- fully-automatic, semi-automatic

- Configuration

- floor-standing, modular

- Container type

- for ampoules, for boxes, for syringes, blister

- Application domain

- for the pharmaceutical industry, for small-scale production

- Production capacity

Min.: 2 p/min

Max.: 8 p/min

Description

At Körber, we package pharmaceutical products more than safely: beyond that our packaging solutions are sustainable, environmentally conscious and patient-friendly.

Your benefits:

Flat cardboard and partition blanks – printable on both sides

Secure automated erecting and gluing

Secure product insertion process (100% verification after insertion)

Over the entire manufacturing and logistics process, this results in concrete advantages for you as a manufacturer of parenterals as well as your end customers, which positively influence both your Total Cost of Ownership (TCO) and your Total Cost of Package (TCP).

For the packaging of very small quantities and clinical studies, you are on the safe side with the carton erector (Dividella NeoTOP Tool T1) and carton sealer (Dividella NeoTOP Tool T9). Both unitsare GMP-compliant and ensure easy and safe handling. The reliable cold gluing of the Dividella NeoTOP Tool from Körber can be converted to hot gluing as production volume increases. With the same mono-material packaging style, this enables seamless up-scaling to semi- or fully-automatic topload cartoners.

Your benefits

Production & manufacturing

Flexible machine platform, fast format changes, secure process through 100% post-loading verification, lower total cost of packaging and total cost of ownership (TCP and TCO)

Logistics & procurement

Flat monomaterial blanks made of cardboard (inbound), compact exterior dimensions (outbound), product protection

Marketing & regulations

Sustainable packaging concept (no plastic), high recognition value thanks to double-sided printable cartons, tamper-evident closure, patient-friendly, safety options, Track & Trace

Catalogs

No catalogs are available for this product.

See all of Körber Pharma‘s catalogsRelated Searches

- Packaging system for the pharmaceutical industry

- Automatic packaging machine

- Floor-standing packaging machine

- Sealing packaging machine

- Blister packaging machine

- Compact packaging machine

- Medical industry packaging machine

- Film packaging machine

- Medicine packaging system

- Inspection system for the pharmaceutical industry

- Horizontal packaging machine

- Automated inspection system

- Bag packaging machine

- Cartoner for the pharmaceutical industry

- Automatic cartoning machine

- High-performance packaging machine

- Capsule packaging machine

- Solids packaging machine

- Floor-standing cartoning machine

- Syringe packaging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.