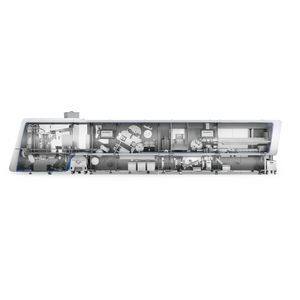

Automatic cartoner P5 continuousfloor-standingmodular

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic, continuous

- Configuration

- floor-standing, modular

- Container type

- for ampoules, for syringes, blister

- Application domain

- for the pharmaceutical industry

- Other characteristics

- high-speed

- Production capacity

500 p/h

Description

To ensure that blisters, ampoules, vials and similar reach patients safely and in compliance with GMP, packaging machines for secondary packaging must meet high requirements. The sideload cartoners from Körber are perfectly adapted to this. The flexible, modular machines allow effortless expansion of a blister, sachet or stick pack systems into a complete, high-performance production line.

Process reliability

Digital counting units ensure precise setting during format changes

Time saving

Excellent accessibility enables fast changeovers as well as short non-productive times due to easy and fast cleaning

Flexibility

Teach-in process for different brochure lengths

Up to 500 cartons per minute can be packed on the P5 high-speed cartoner. It delivers maximum performance even with large formats. Thanks to its modular design, the integration of further functionalities at a later date makes the machine a worthwhile and future-proof investment.

High flexibility

Smooth blister transfer and stack building using delta robotic technology which is fully integrated in our HMI. Format changeover is extremely simple, as it is only necessary to change the robot’s suction arm by using a quick-release clamp

Patented carton erecting unit

The patented carton separation unit ensures a stable packaging process. The carton magazine is designed so that individual cartons are separated positively for the utmost gentle removal by the suction wheel

Best accessibility

Extremely short and compact infeed station. Swiveling to the operator side for best access for cleaning and tool-less format change-over.Continuous insertion station with overload protection and leaflet pre-infeed

Catalogs

Dividella Monomaterial Packaging

12 Pages

Related Searches

- Körber Pharma packaging system for the pharmaceutical industry

- Körber Pharma automatic packaging system

- Körber Pharma floor-standing packaging system

- Körber Pharma sealing packaging system

- Körber Pharma blister packaging system

- Compact packaging machine

- Körber Pharma medical industry packaging system

- Inspection system for the pharmaceutical industry

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Bag packaging machine

- Körber Pharma cartoner for the pharmaceutical industry

- Automated inspection system

- Körber Pharma automatic cartoner

- High-performance packaging machine

- Capsule packaging machine

- Solids packaging machine

- Körber Pharma floor-standing cartoner

- Liquid packaging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.