- Medical Technical Facilities

- Mortuary

- Formalin scavenging system

- KUGEL medical GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Formalin scavenging system ESS 1750

Add to favorites

Compare this product

Characteristics

- Applications

- formalin

Description

Special working table with integrated ventilation system. Within the entire work surface the airabsorbed downwards whereby harmful vapour can be absorbed in an optimal way. The working table should be connected to an exhaust-air-system provided by the customer.

Complete construction is made of ground stainless steel (material no. 1.4301 - ANSI 304)

base frame with three hinged front doors with edged-on strip handle as well as three-dimensional adjustable door panels

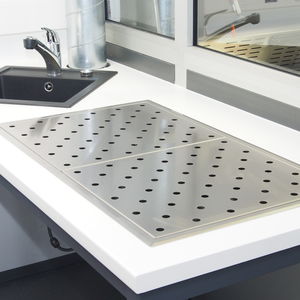

Within the perforated plates area a removable inlayed grading screen (flap mechanism) to separate liquid substance from solids

On the left a seamless welded basin 400 x 400 x 200 mm with standpipe valve (except ESS-1200: basin is not included in standard scope of delivery!)

Basin with integrated ventilation system with right or left side option

Mixing tap with hand sprinkler

Very stable perforated working plates (approx. 10 mm lower than the circumferential edging), perforation D17, T60

Exhaust air capacity with the perforated working surface min. 0.4 m/sec

Integrated connecting pieces with flow rate Regulation

Integrated sprinkler system below perforated working plates with regulating valve

Connecting pieces for exhaust air with right or left side option

top part incl. 3-tier plexi glass construction

incl. 20 litres Container for waste formalin with sensor Level

Container for tissue waste is not included in scope of delivery

an eye shower with shower head is mounted to the table

Different dimensions available upon request.

TECHNICAL DATA

Dimensions W/D/H: 1750 x 850 x 850 mm

Exhaust Air capacity: Min. 1500 m³/h

Catalogs

Laboratory Equipment

106 Pages

Related Searches

- Logistics cart

- Nursing trolley

- Medical device cart

- Rectangular table

- Stainless steel cupboard

- Cupboard with drawer

- Stainless steel table

- Stretcher

- Gray cupboard

- Laboratory cupboard

- Mobile table

- Height-adjustable cart

- Refrigerated mortuary cabinet

- Front-loading mortuary cabinet

- Modular shelving unit

- Body tray mortuary cabinet

- Refrigerated mortuary cabinet with door

- Open-structure shelving unit

- Transfer cart

- Stainless steel shelving unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.