- Furniture, Logistics

- Medical office, Examination room

- Formalin dispensing workstation

- KUGEL medical GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

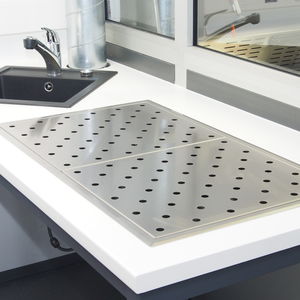

Formalin dispensing workstation with sinkstainless steel

Add to favorites

Compare this product

Characteristics

- Applications

- for formalin dispensing

- Equipment

- with sink

- Other characteristics

- stainless steel

Description

We offer a central supply system for different kinds of quemicals such as formalin, alcohol and xylol for easy, fast and safe dispensing of said liquids. Dispensing faucets, one faucet per chemical, are installed on a special working table. An "ON" button triggers the compressed air diaphragm pump in the ex protection area where the quemicals are stored in large barrels. The quemicals are transferred through stainless steel pressure lines for 5 Minutes to the dispensing faucet at the special working table. The liquid quantity is controlled through an integrated ball valve (8 liters/minute). A green alarm light lightens up if the pump/faucet is in use. All faucets can be used at the same time. Contaminated air is constantly vacuumed out downwards at the working table in order to underscore MAC (maximum allowable concentration) values for formalin as well as to reduce the formation of inflammatory mixture of alcohol and xylol (air capacity at least. 600 m³/h - depending on working table size).

New material (formalin/alcohol/xylol) is stored in adequate barrels in an ex protection area. The pumps have suction lance connections that are simply inserted into the barrels. The self priming pumps have a dry running protection. Waste formalin, alcohol and xylol are disposed through a waste sink at the special working table and are able to drain downwards freely into a connection barrel in the ex protection area.

A sensor level controls the filling of the connection barrels. The "BARREL FULL" light lightens up at the special working table when approximately 80% of the barrel is full.

Catalogs

No catalogs are available for this product.

See all of KUGEL medical GmbH & Co. KG‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.