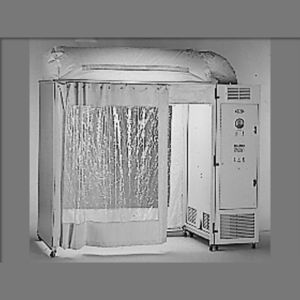

Isolation animal research cage Micro-Isolator®modular

Add to favorites

Compare this product

Characteristics

- Applications

- isolation

- Configuration

- modular

Description

When used in a static condition, the Micro-Isolator® system functions as an animal-sized Petri dish. The cage may be handled without breaking the cage level microbiological barrier. Although air exchange rates in a static (non-ventilated) Micro-Isolator® may be adequate, ammonia, carbon dioxide and humidity levels can only be regulated with HEPA filtered (99.99% efficient to 0.3 micron particles) air supply systems, such as with individually ventilated cages.

When used in a HEPA filtered condition, each cage is docked on a Ventilated Rack that provides cage level supply and exhaust air ventilation. These systems assure barrier protection for laboratory animals and sustained regulation of airborne particulates, helping protect both animal and personnel. Positive supply air flow is delivered to each cage directly, protecting animals in a HEPA filtered air environment. Cage exhaust air is then captured indirectly as it exits above each cage filter top, assuring barrier protection for personnel.

By practicing appropriate aseptic techniques, the Micro-Isolator® may be opened in a Lab Products, llc. laminar flow Stay-Clean™ Workbench that provides Class 100 laminar flow air. Cage changes and animal manipulations may be performed within the workbench without breaking the microbiological barrier from cage to cage.

Catalogs

Related Searches

- Veterinary cage

- Modular veterinary cage

- Animal research cage

- Modular animal research cage

- Rodent animal research cage

- Mice animal research cage

- Polypropylene veterinary cage

- Metabolic cage

- Stainless steel animal research cage

- Modular metabolic cage

- Veterinary isolation cage

- Isolation animal research cage

- Rodent veterinary cage

- Ventilated animal research cage

- Polycarbonate animal research cage

- Polypropylene animal research cage

- Ventilated veterinary cage

- Guinea pig animal research cage

- Rabbit animal research cage

- Disposable animal research cage

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.