Stripping laser machine Optec ECHO 360workstationUV

Add to favorites

Compare this product

Characteristics

- Other characteristics

- stripping, UV, workstation

- Wavelength

193 nm, 248 nm

Description

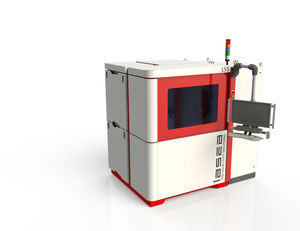

A turnkey workstation from the A-thermal laser experts.

Throughput equal to multiple mechanical & chemical stripping stations.

Residue-free ablation of most polymers and other coating materials No handling or wire rotation needed for perfect results every time.

Nothing strips fine-wire like a UV laser. with few exceptions, and none do it better than the Optec Echo 360 with it deep UV, air-cooled, small format EXCIMER laser.

The Echo 360 is fast, versatile and safe. Optec’s intuitive Process Pro™ software control makes it easy to operate, with minimal instruction and rapid change over to different wire gauges.

The Echo 360 serves aerospace, MEMS, automotive, consumer electronics, telecom and medical devices, including cardiac rhythm, neuro, electro physiology and many other demanding applications.

Strip 360o without rotating the wire

Down to 60 AWG

Non-contact, no damage to the core

Residue-free & oxidation-free

No chemicals or hazardous waste

More than 2X faster than UV YAG lasers

Single, bifilar, trifilar, quadfilar

Wire separation & cutting options

All wire types, including magnetic

Reel-to-reel & reel-to-cut & singles

Compact, self-contained, mobile

Color touch-screen display

1B+ shots without factory service

Conventional lasers, such as a 355 nm YAG, have a focused, Gaussian beam that scans the insulator using the highest intensity ‘point’ of the beam.

This makes it difficult to regulate the amount of energy needed to strip the coating without changing the surface of the metal conductor.

The Echo 360’s flat-top beam ablates a large area of the coating evenly by means of aperture imaging and ECHO technology.

Catalogs

No catalogs are available for this product.

See all of LASEA‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.