Data management system Exaltatraceabilitytrainingmedical

Add to favorites

Compare this product

Characteristics

- Function

- data, traceability, training

- Applications

- medical, for microscopy

Description

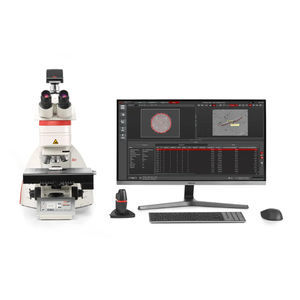

Production and quality control (QC) of implantable medical devices require a great deal of microscopic visual inspection.

Current manual visual inspection solutions often have a drawback. Difficulty to ensure consistent visual inspection according to standard procedures across multiple operators. Additionally, with manual solutions it is challenging to generate reports, track approvals, and store data in an efficient way.

Exalta is a smart device for traceable microscopy that helps you deliver reliable quality results. With Exalta, you can:

- Inspect reliably across multiple operators

- Generate robust reports efficiently

- Be ready for 21 CFR Part 11 and GxP

Inspect reliably across multiple operators

Guide the operator with step-by-step work instructions

Production or quality managers can use Exalta to create various sample-specific work instructions to help ensure consistency across multiple operators working at different workstations.

Additionally, as a manager you can spend less time training new operators, rapidly adapt standard procedures to new requirements, and easily introduce and distribute revisions of procedures to all workstations.

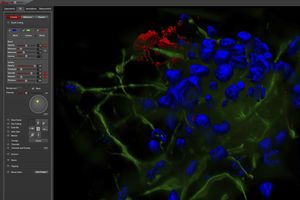

Step-by-step work instructions help operators to

Stay focused on each step and avoid missing one

Screen the entire sample and evaluate potential defects according to standard procedures

Follow reliably standard procedures and minimize deviations

Consistent results and pass / fail decisions

Exalta helps operators to consistently perform visual inspection and make pass / fail decisions during their daily work with:

Catalogs

Exalta

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Leica analysis software

- Leica visualization software

- Control software

- Leica laboratory software

- Windows software

- Automated software

- Acquisition software

- Scan software

- Measurement software

- Education software

- Data analysis software

- Image analysis software

- Sharing software

- Medical management system

- Interpretation software

- Screening software

- Navigation software

- Leica archiving software

- Leica digital microscope software

- Laboratory management system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.