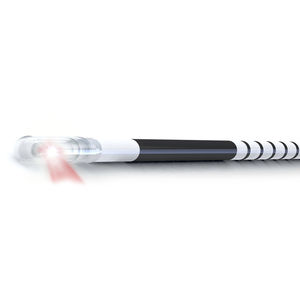

Surgical laser optical fiber Bare

Add to favorites

Compare this product

Characteristics

- Applications

- for surgical lasers

Description

You may choose between the classic flat tip design or alternative shapes like a ball tip, conical tip, spherical tip and more. An integrated handpiece is also available. By catering to a patient’s anatomy on a case-dependent basis, access to the treatment site can be improved and the laser’s energy can be transmitted most efficiently.

Many variations of our Bare Fiber are available, and multiuse versions exist as well. Steam autoclave reconditioning helps reduce expenses on consumables for each treatment session.

Complementary with the Bare Fiber, the Dual LuerLock Handpiece can be used for precise alignment of the fiber tip to the tissue that needs to be treated.

To improve in-coupling of the laser beam into a thin and flexible optical fiber, Tapered Bare Fibers can be manufactured. The connector of such tapered fibers has a larger fiber diameter than the diameter at the distal end. This design makes it possible to couple high-power lasers into the optical fiber safely. The large fiber is tapered down to the target diameter, which is smaller and more flexible so that it is able to reach a remote treatment site.

Lightguide can manufacture taper ratios as high as 4:1 using sophisticated equipment in serial production. For example, our Tapered Bare Fiber can convert a 400 µm beam diameter beam into a 200 µm distal tip at affordable costs. Other typical taper ratios are 2 to 1 and 1.36 to 1. The working principle of a fiber down-taper is illustrated below.

Catalogs

Bare Fiber

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.