- Laboratory

- Physico-chemical analysis

- Laser diffraction particle size analyzer

- Malvern Panalytical

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

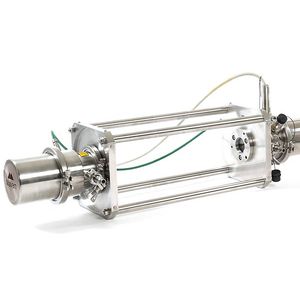

Laser diffraction particle size analyzer Insitec Dryfor the pharmaceutical industryfor the food industryfor environmental analysis

Add to favorites

Compare this product

Characteristics

- Technology

- laser diffraction

- Applications

- for the pharmaceutical industry, for the food industry, for environmental analysis

- Other characteristics

- online

Description

The industrially robust, technologically proven process particle size analyzer.

Engineered to withstand the rigors of the process environment, Insitec Dry particle size analyzers use laser diffraction technology to measure particles in the size range 0.1 to 2500 µm. Insitec Dry can be configured to suit practically every dry particulate process, delivering real-time monitoring and control.

Insitec Dry online particle size analyzers deliver fully automated real-time - or manual at-line - size measurement of particulates, in continuous and batch processes having pneumatic or gravity-fed streams. They are used to monitor and control processes ranging from abrasive bulk powders to foods, fine chemicals and pharmaceuticals with strict hygiene standards and subject to stringent regulatory control. To ensure representative sampling, process interfaces are tailored to meet custom needs whether pilot scale or hundreds of tonnes per hour. Every Insitec Dry system offers:

Base model hardware manufactured to GAMP5 standards and compatible with CIP/SIP requirements to meet specific manufacturing specifications

Easy to use software and fully automated operation to minimize training requirements and release operator time

Integration with existing control platforms to simplify development of automated control protocols

High reliability of >95% with little downtime, minimal maintenance and maximum ROI.

Features and benefits

Overview

All Insitec installations are tailored to the unique requirements of the application. They range from simple at-line, manually-fed systems to fully automated, validated on-line solutions for continuous monitoring and multivariate control.

VIDEO

Related Searches

- Analysis software

- Viewer software

- Control software

- Laboratory software

- Reporting software

- Malvern spectrometer

- Acquisition software

- Scan software

- Treatment software

- Measurement software

- Benchtop spectroscope

- Education software

- Chromatograph

- Data analysis software

- 3D software

- Compact spectrometer

- Research spectroscope

- Automatic sampler

- Spectrometer for the pharmaceutical industry

- Malvern particle size analyzer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.