- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

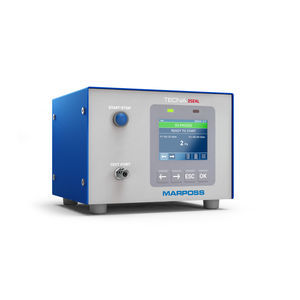

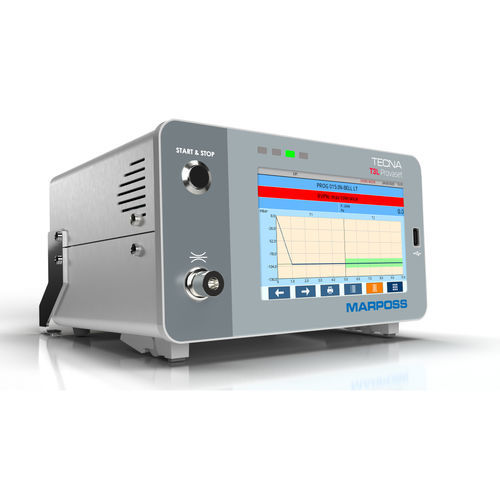

Differential pressure decay leak tester TECNA T3LDfor bagsfor bloodlinesfor the pharmaceutical industry

Add to favorites

Compare this product

Characteristics

- Applications

- for bags, for bloodlines, for the pharmaceutical industry, packaging, laboratory, for valves, for bottles, for medical disposables, for filters, for infusion lines, for luer connectors

- Type

- differential pressure decay

- Configuration

- benchtop, compact

- Other characteristics

- USB, with touchscreen, color display, Ethernet, serial line, ProfiNet, Modbus, electronic regulation

Description

T3LD is an innovative device for leak tests by differential pressure method. By measuring the pressure difference between the product being tested and a reference sample, it is possible to reduce test time and heighten the sensitivity.

PERFORMANCE

The touchscreen interface, with a colour display and the real-time visualization of the tests, makes the programming and the use simple and immediate.

Its high measurement resolution and the test accuracy, in combination with the electronic regulation of the filling pressure, allow to perform not only leak tests but also destructive burst tests, safety valves opening checks, volumetric control, obstruction tests and “in bell” tests on sealed products or by interception method.

CONNECTIVITY

T3LD has digital I/O interfaces to PLC connection, USB host, two serial lines RS485/RS232 for PC, Ethernet interface. The control of external automations, the interface with barcode, QRcode readers and printers make T3L a complete and suitable instrument for the most modern production applications. The software manager dedicated permits to collect and manage data of the tests, to set up the parameters programming and do SPC analysis of tests data.

Leak test full-scale ranges: up to 30 bar and vacuum

High measurement resolution: up to 0.1 Pa

Colour 7” LCD display – graphic test view

Fully Interfaceable: Digital I/O for PLC – USB for PC – Serial lines RS485/232 - Ethernet

Test Data Storage on USB pen drive or LAN/Ethernet/Profinet

External Automations and devices control: printer, barcode and QRcode reader – remote control keypad – external valve for volume check and tests in sealed ‘bell’ – air filters

VIDEO

Catalogs

No catalogs are available for this product.

See all of MARPOSS‘s catalogsRelated Searches

- MARPOSS leak tester

- Pressure leak tester

- MARPOSS medical device leak tester

- MARPOSS benchtop leak tester

- MARPOSS leak tester for the pharmaceutical industry

- MARPOSS packaging leak tester

- Compact leak tester

- MARPOSS USB leak tester

- Flow leak tester

- Vacuum leak tester

- Laboratory leak tester

- MARPOSS leak tester with touchscreen

- MARPOSS valve leak tester

- Pneumatic leak tester

- MARPOSS bottle leak tester

- MARPOSS color display leak tester

- High-performance leak tester

- LAN leak tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.