- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Revision acetabular prosthesis MPACT®cementless

Add to favorites

Compare this product

Characteristics

- Surgical application

- revision

- Fixation type

- cementless

- Acetabular cup diameter

Max.: 76 mm

(2.99 in)Min.: 42 mm

(1.65 in)

Description

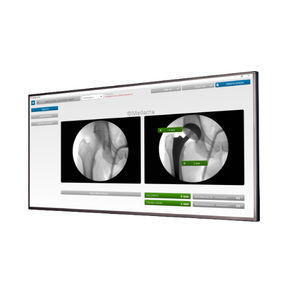

Mpact System is a comprehensive hemispherical cup platform featuring different shell and liner designs and materials allowing for efficiently treating the majority of the clinical cases from primary to revision surgeries, according to patients’ needs.

The Mpact system makes use of different advanced materials and manufacturing technologies.

Both MectaGrip and 3D Metal allow for designing and manufacturing implants featuring a high friction coefficient, increasing grip at the bone interface, thereby obtaining a superior primary stability. Moreover, the porous structure parameters in line with the commonly accepted parameters create a favorable environment for the bone.The efficient connection with the bone has been validated by means of an animal study in young sheep.

MectaGrip

MectaGrip is a porous coating treatment applied to the Mpact shells, consisting of a layer of commercially pure titanium deposited through a special Vacuum Plasma Spray technique (VPS). Titanium porous coating allows for an enhanced biocompatibility, thanks to the pure titanium composition and optimized porosity.

3D Metal

3D Metal is an advanced biomaterial structure that is finely engineered for the bone. It is made of Titanium alloy (Ti6Al4V), and it is obtained by means of 3D printing technology, an innovative one-step layer-by-layer additive manufacturing process (not a coating).

This advanced technology allows for designing different engineered 3D net structures starting from a CAD model in a precise, predictable and reproducible manner. By means of a single technology it is possible to efficiently face most clinical cases, from standard primary to complex revision surgeries.

Catalogs

Related Searches

- Bone plate

- Grasping tweezers

- Reusable tweezers

- Endoscopy forceps

- Interbody fusion cage

- Orthopedic surgery surgery set

- Tissue grasping tweezers

- Bent tweezers

- PEEK interbody fusion cage

- Femoral stem

- Lumbar interbody fusion cage

- Anterior interbody fusion cage

- Arthrodesis plate

- Knee prosthesis

- Sterile surgical set

- Acetabular prosthesis

- Metallic arthrodesis plate

- Screw-rod unit

- Posterior spinal fusion system

- Cervical interbody fusion cage

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.