- Medical Imaging

- Radiology

- Planning software

- mediCAD Hectec GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Planning software CTsurgeryhip

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- planning

- Applications

- CT, surgery

- Area of the body

- hip

- Type

- 3D

- Other characteristics

- server

Description

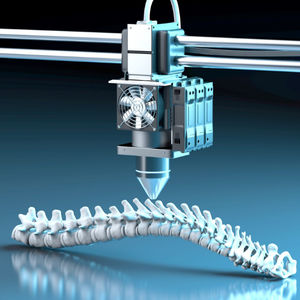

Until now, the implant manufacturing process from prototyping an implant design to the implantation of custom-made protheses in orthopedic surgery was very time-intensive.

Introducing our new feature “Individual prothesis”. Through this new implementation the time-intensive process of creating a customized implant will be significantly reduced.

Advantages

Easy to use

Fast data transmission

Eco-friendly

Cost saving

Improved patient outcomes

For optimal resolution in CT scans a layer thickness of up to 1 mm is recommended

Audit proof archiving of all data in PACS system

Continued development in mediCAD®

The new “Individual prothesis” feature is also enhanced for mediCAD® 3D Hip. While completing surgical planning with a preferred implant manufacturer surgeons can choose the “Individual prothesis” feature and an individual form of the implant manufacturer appears. The doctor fills out and uploads his current plan to a shared platform with the implant manufacturer.

A chat and exchange platform will soon be active to improve communication between customers and manufacturers.

Catalogs

No catalogs are available for this product.

See all of mediCAD Hectec GmbH‘s catalogsRelated Searches

- Radiology software

- Scheduling software

- Software module

- Surgical software

- CT software

- Server software

- 3D software

- Clinical software module

- Design software module

- 2D medical software

- Radiology software module

- Orthopedic software

- Scheduling software module

- Surgical software module

- Hip software

- Simulation software module

- Knee software

- Pelvis software

- 3D simulation software module

- Joint software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.