- Medical & Pharmaceutical industry

- Medical industry

- Medisam İnşaat Sağlık Sistemleri Ltd. Şti.

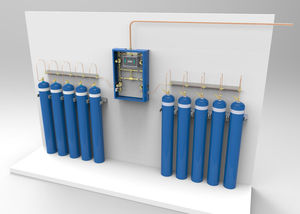

Hospital conveying system parts

Add to favorites

Compare this product

Characteristics

- Application domain

- for hospitals

- Product transported

- parts

Description

The work of transporting or dosing granular materials with the help of compressed air or different propellants is called pneumatic transport or pneumatic transport. The working principle of the pneumatic conveying system is based on the logic of transmitting the kinetic energy of the compressed air stream to the granular product to be transferred. In pneumatic transfer processes, each product transported with the help of compressed air is first mixed with air and then separated from the air. While the mixing process is done with the help of rotary valves (air lock), loading stations and venturi, the separation process is done with the help of filters.

Compressed air, which is the basic need of pneumatic conveying systems, is provided by side channel blowers, roots blowers or high flow fans, depending on the capacity and flow rate of the air required by the system. Although pneumatic conveying systems seem to be mixing the product transferred with compressed air and then separating the product with the help of a filter, it is a job that requires serious engineering work and experience. The powders to be transported can become highly explosive under a certain pressure and temperature. Products such as sugar, flour and starch, which seem extremely innocent, can become extremely dangerous products with faulty design and selection.

Transporting the material in a homogeneous state,

No loss in the transferred product,

The system does not take up much space,

Being hygienic because it is closed to the outside environment,

Low maintenance costs due to few moving parts,

Together with automation, it provides a serious labor saving.

Other Medisam İnşaat Sağlık Sistemleri Ltd. Şti. products

Our Products

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.