- Products

- Degassing module

- Meditech Technologies India

Laboratory degassing module BHFPPRC

Add to favorites

Compare this product

Characteristics

- Applications

- laboratory

Description

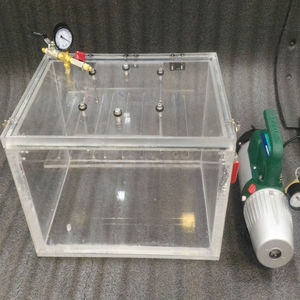

A pressure pot for resin casting manufactured by Burhani Hardware And Fittings is required for bubble-free and air-trap-free resin castings. This is especially critical in creating clear resin castings applications, as trapped air can affect the appearance of a crystal clear casting. The BHFTECH Pressure Pot for resin is designed for use in applying pressure to force air out of resin and to force resin into thin sections of a mold. This eliminates air bubbles and air traps in the cured castings

This is the best pressure pot for resin casting includes a gauge and all the other pneumatic fittings, valves and gauges . However, you will also need to purchase an air compressor of at least 3 H.P. and a ¼-inch adapter or coupling to attach the air compressor to the pot. Both items are readily available with Burhani Hardware and Fittings.

Pressure Pot Specifications: Capacity as per below table

How to use a pressure pot for resin

setting up a pressure pot for casting resin under pressure is the best way to make high quality resin castings. This is especially true with difficult recesses and complex molds. Pressure casting compress air to sizes undetected by the human, creating a virtually bubble less casting.

using a pressure pot for resin : Mix your material in accordance with the directions and pour it into your mold. Place the mold into the pressure pot. Place the lid on the pressure pot and locate the (4) locking slots on the cover lining them up with the (4) swing up bolts on the tank. Place the (4) swing bolts into the slots in the cover and secure the (4) hand nuts tightly on the cover. Make certain the nuts are secured tightly before pressurizing the tank.

Catalogs

No catalogs are available for this product.

See all of Meditech Technologies India‘s catalogsOther Meditech Technologies India products

Blood Bank equipment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.