- Laboratory

- Laboratory infrastructure

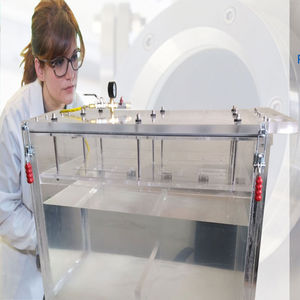

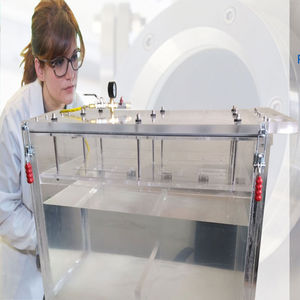

- Glove box for the pharmaceutical industry

- Meditech Technologies India

Laboratory glove box BHFAGB53-225for the pharmaceutical industryR&Dbenchtop

Add to favorites

Compare this product

Characteristics

- Applications

- laboratory, for the pharmaceutical industry, R&D

- Configuration

- benchtop

- Other characteristics

- acrylic, vacuum

Description

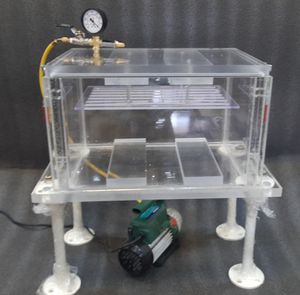

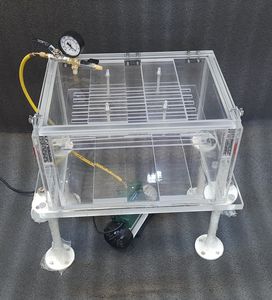

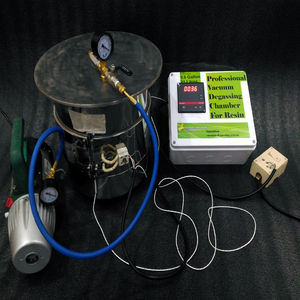

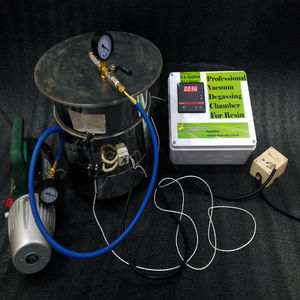

Glove Box supports vacuum and degassing operations.

Vacuum cycling provides a fast, economical way to achieve

extremely low moisture and oxygen levels inside the chamber. During

each cycle, a vacuum pump connected to the glove box removes the

chamber environment, and with it moisture and oxygen. At the end of

the vacuum cycle, the chamber is backfilled with a clean, dry process

gas (commonly nitrogen or argon) to restore neutral pressure. This

cycle can be repeated as many times as necessary to attain the desired

low humidity, low oxygen conditions.

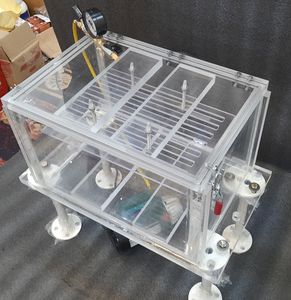

BHFTECH Vacuum Acrylic Vacuum Box With 225 Liters working Space. This is the smallest chamber

available with 2 Glove Port and 300x300mm Wide Door Opening. Due to its small size, it can be used

different application as a standalone system or stacked for desiccators or any other application. This Glove

Box can be used for testing, conditioning, fabrication and storage in university research, biomedical,

electronic, electrostatic, pharmaceutical, R&D and other application where a small environment is required.

User can control and operate and wide range of system to meet their criteria.

Accessories includes PID controllers for Heating and cooling systems along with humidification and

dehumidification. This glove box can be used from Basic to Full range of Temperature and Humidity control.

225 Liters working space

size: 92 x 61 x 46 cm

Construction Material: Clear Acrylic

Door: left side or right side.

Seal : High Quality Rubber Seal

Gloves : Latex Rubber for 6 inch Ports

Temperature: <32-122°F (0-50°C)

Humidity: <1-100% RH

Door with 300mm x 300mm wide access opening

The Glove box is Available with or without 150mm glove ports

Catalogs

No catalogs are available for this product.

See all of Meditech Technologies India‘s catalogsOther Meditech Technologies India products

Vacuum Equipment BHFVACCUM

Related Searches

- Upright refrigerator

- 1-door refrigerator

- Laboratory freezer

- Laboratory refrigerator

- 1-door freezer

- Laboratory incubator

- Stainless steel refrigerator

- Heating furnace

- Laboratory furnace

- Temperature-control laboratory incubator

- Climatic test cell

- 2-door refrigerator

- Temperature test cell

- Hospital refrigerator

- Stainless steel freezer

- Humidity test cell

- Refrigerator on casters

- Blood bank refrigerator

- 1-door test cell

- Laboratory test cell

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.