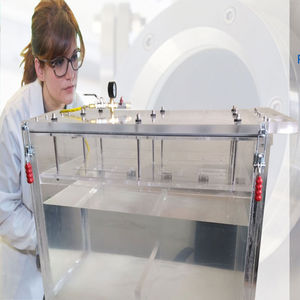

- Laboratory

- Laboratory infrastructure

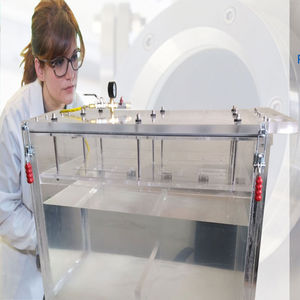

- Vacuum test chamber

- Meditech Technologies India

Vacuum test chamber BHFFB

Add to favorites

Compare this product

Characteristics

- Other characteristics

- vacuum

Description

Bubble leak testing of tank bottom plate welds and shell to bottom plate welds

The BHFTECH vacuum box has been designed for the operators according to API 650/653

recommendations. Bubble leak or vacuum box testing is an integral part of tank

inspections as required by the American Petroleum Institute (API) and other international

standards associations to establish the condition of tank bottom plate welds and shell-tobottom

plate welds

Features

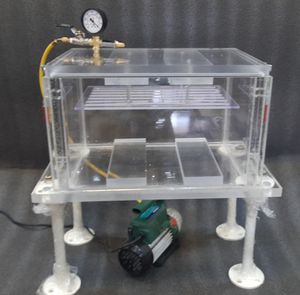

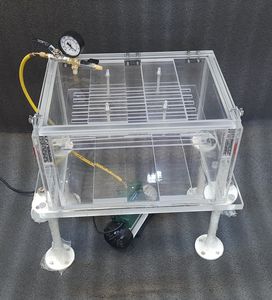

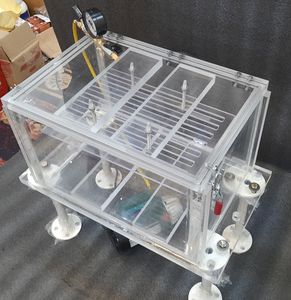

Designed to API 650/653 recommendations

750 mm (29.53 in) weld inspection length, improves

inspection times and reduces operator fatigue

Integrated LED lights provide the required light

intensity as specified by API and ASME inspection

standards

Screen glare and shadows from external light sources

are eliminated

Calibrated vacuum relief valve ensures the correct

vacuum is generated, too high a vacuum can damage

the vacuum box and cause injury to the operator

Superior build quality with robust cast aluminum

body

Two-stage seal design to improve initial vacuum,

especially on large lap welds

Electric vacuum pump or compressor driven

VIDEO

Catalogs

No catalogs are available for this product.

See all of Meditech Technologies India‘s catalogsOther Meditech Technologies India products

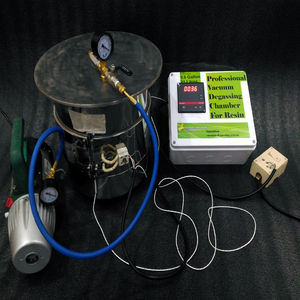

Vacuum Equipment BHFVACCUM

Related Searches

- Upright refrigerator

- 1-door refrigerator

- Laboratory freezer

- Laboratory refrigerator

- 1-door freezer

- Laboratory incubator

- Stainless steel refrigerator

- Heating furnace

- Laboratory furnace

- Temperature-control laboratory incubator

- Climatic test cell

- 2-door refrigerator

- Temperature test cell

- Hospital refrigerator

- Stainless steel freezer

- Humidity test cell

- Refrigerator on casters

- Blood bank refrigerator

- 1-door test cell

- Laboratory test cell

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.