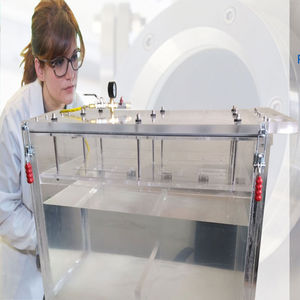

- Laboratory

- Laboratory infrastructure

- Heating oven

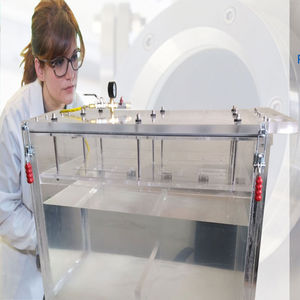

- Meditech Technologies India

Heating oven BHF2020laboratoryvacuumfor resin

Add to favorites

Compare this product

Characteristics

- Function

- heating

- Applications

- laboratory

- Type

- vacuum

- Designed for

- for resin

- Sterilization chamber material

- stainless steel

Description

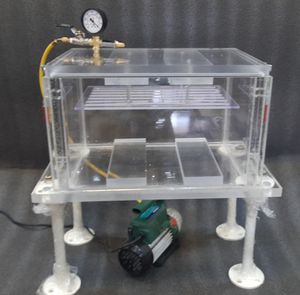

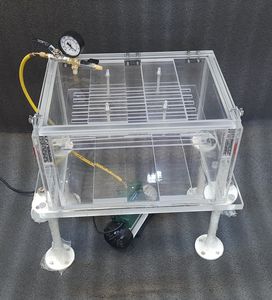

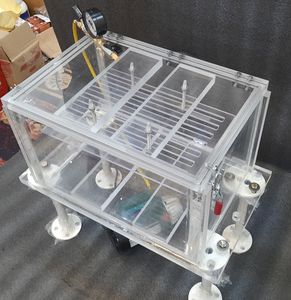

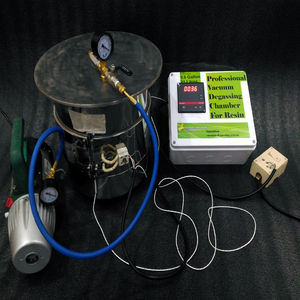

Heated Vacuum Oven With Pump

Burhani Vacuum oven is provided with digital electronic control, built-in overtemperature

protection, and a fully flexible vacuum/purge/release system for a range

of applications including those that require elevated temperature in reduced

atmosphere.

These heated vacuum oven Chamber provide precise and fast heating and heat

transfer which helps minimize operation time. These vacuum ovens are compliant

with the highest level of requirements for heating applications under a vacuum. LED

display of actual and set point temperature. Temperature Range available as per

customer requirements. Digital microprocessor control

Heated Vacuum degassing is the process of using vacuum to remove

gases from compounds which become entrapped in the mixture when

mixing the components. To assure a bubble-free mold when mixing

resin and silicone rubbers and slower-setting harder resins, a vacuum

chamber is required. A small vacuum chamber is needed to eliminate

air bubbles for materials prior to their setting. The process is fairly

straightforward. The casting or moulding material is mixed according

to the manufacturers directions.

Product Features of the Heated Vacuum Degassing Chamber

Stainless steel chamber for long-term air-tightness performance.

Heavy Duty Industrial Heating System

Adjustable Digital Temperature display and Controller

Various Temperature Ranges available on request

Burhani Vacuum chamber has a rounded edge at the top, for the protection of silicone gasket.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Meditech Technologies India‘s catalogsOther Meditech Technologies India products

Vacuum Equipment BHFVACCUM

Related Searches

- Upright refrigerator

- 1-door refrigerator

- Laboratory freezer

- Laboratory refrigerator

- 1-door freezer

- Laboratory incubator

- Stainless steel refrigerator

- Heating furnace

- Laboratory furnace

- Temperature-control laboratory incubator

- Climatic test cell

- 2-door refrigerator

- Temperature test cell

- Hospital refrigerator

- Stainless steel freezer

- Humidity test cell

- Refrigerator on casters

- Blood bank refrigerator

- 1-door test cell

- Laboratory test cell

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.