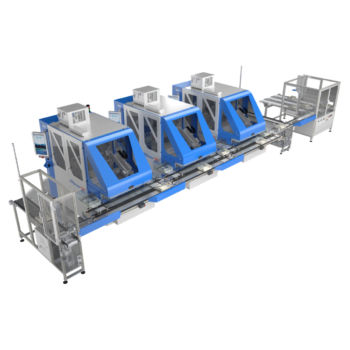

Laboratory conveyor EZLine Dualmedicalfloor-standing

Add to favorites

Compare this product

Characteristics

- Application domain

- medical, laboratory

- Configuration

- floor-standing

Description

The EZLine Dual feeder is an automated conveyor system for high-volume labs.

With its twin trays flow, it provides a flexible job management system, able to handle the loading of an edging line of several MEI machines with a throughput of up to 600 pairs/hour.

EzLine Dual receives the VCA job trays from the factory conveyor or MEI de-stacker, downloads the OMA edging data from the server, and handles the working load of the entire line.

The control unit has the map of the capacity of each machine and sends the job to the freest one, accordingly with the job specification and machine capacity.

At the entrance of each machine, a barcode scanner reads the job ticket and decides if the tray has to stop or can proceed to the end of the line if it is already finished.

EZLine Dual can manage hybrid edger composition (with old MEI machines, too) and allows mixed machine directions (right to left and left to right) in the same line.

BENEFITS

High troughput, up to 600 pairs/hours

Twin trays flow

Mixed machine direction (right to left and left to right)

Hybrid edger composition (with old mei machines, too)

Flexible input-output definition

COMPLETELY RENEWED SERVER ‘STAND’

with a barcode scanner that makes it easy to find out the job story

VIDEO

Catalogs

No catalogs are available for this product.

See all of MEI System‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.