- Dental

- Dental practice

- Polymer acrylic dental prosthesis

- Merz Dental GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

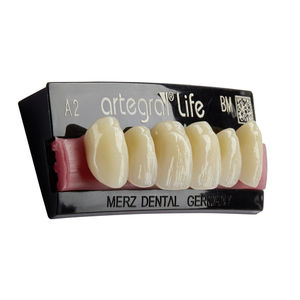

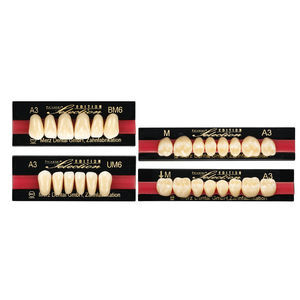

PMMA dental prosthesis artegral® anterior teethposterior teethprefabricated

Add to favorites

Compare this product

Characteristics

- Material

- PMMA

- Tooth type

- anterior teeth, posterior teeth

- Other characteristics

- removable, anatomical, prefabricated

Description

Oriented on the demands for manufacturing removable superstructures, the artegral® tooth series meets contemporary requirements. The special features of the artegral® include corporeality like a natural tooth, universal function even with natural antagonists, a moderate cusp inclination and time-saving handling.

The surface texture, in conjunction with the labial flanges, creates a natural light refraction. The integration of the natural course of the flanges gives a single tooth character that has not yet been achieved with prefabricated teeth. Volume there, where it makes sense, so that precision anchoring elements, telescopes and implants can be covered with ease.

The set-up of the posterior teeth is efficiently supported by an integrated set-up aid. Regardless of the occlusion concept, the posterior teeth find their way safely into the tripodised centric. Sagittal and transversal compensation curves are set almost automatically, especially with coverdentures or full denture restorations.

Thanks to the CAD/CAM manufacturing process the teeth are mirrored, there is no difference between the right and left side. As a result, even guidance paths are guaranteed in the balanced occlusion under tooth contact.

Contemporary removable prosthetics require intelligent materials. They should be abrasion resistant and fracture-proof to guarantee a long wearing life in tertiary structures. Two material compositions are available for the artegral® posterior: Filler-free Organic Modified Polymer-Network - OMP-N® and artegral® HD with inorganic, Highly Modified Polymer-Network

Anterior

Moulds and sizes according to the CBI® system

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Dental material

- Restoration dental material

- Analysis software

- PMMA dental material

- Cupboard with drawer

- Dental prosthesis dental material

- Viewer software

- Control software

- Modeling dental material

- Dental crown material

- Laboratory software

- Ceramic dental material

- Dental bridge material

- Windows software

- Biocompatible dental material

- Laboratory cupboard

- White cabinet

- Wax dental material

- Modular cupboard

- Casting dental material

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.