Annealing furnace GLOW CUBE-200+heatingfor dental laboratoriesfor metal

Add to favorites

Compare this product

Characteristics

- Function

- heating, annealing

- Applications

- for dental laboratories

- Designed for

- for metal

- Number of doors

- 1-door

- Temperature range

1,200 °C

(2,192 °F)

Description

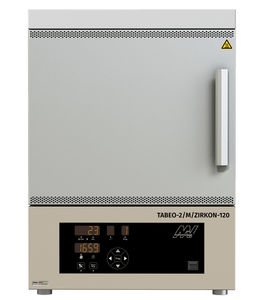

1. GLOW CUBE-200

The GLOW CUBE-200 has a 4-sided wire-heated heating chamber; it is used for annealing processes without inert gas. The generously dimensioned heating chamber offers space to anneal SLS or SLM models with a platform size of up to 200 x 200 mm (model height up to 250 mm) with low stress. Up to 4 round platforms with a diameter of 100 mm can also be heat-treated simultaneously. The GLOW CUBE-200 is therefore the ideal annealing furnace for use in dental laboratories and industrial companies with large volumes of 3D-printed metal models. Programming with up to 9 levels is quick and intuitive using the controller with clear 4-line display.

2. GLOW CUBE-200+

The Plus stands for the additional equipment of the GLOW CUBE-200 with a protective gas function and a heating chamber rapid cooling with compressed air. These functions are activated under program control. A temperature-monitored inert gas box made of special steel is used for heat treatment under inert gas. The capacity of the protective gas box is designed so that 4 round model platforms with a diameter of 100 mm or a square platform up to 200 x 200 mm (model height up to 100 mm) can be heat treated. The shielding gas flow rate and the compressed air flow rate for rapid cooling of the heating chamber are infinitely adjustable manually via two separate control modules.

Catalogs

Related Searches

- Heating furnace

- Laboratory furnace

- Benchtop furnace

- 1-door furnace

- Stainless steel furnace

- Drying furnace

- Mihm-Vogt dental laboratory oven

- Exhaust hood

- Stainless steel hood

- Mihm-Vogt high-temperature oven

- Muffle furnace

- Dental laboratory hood

- Heating oven

- Preheating furnace

- Zirconia furnace

- High-performance furnace

- Annealing furnace

- Modular fume hood

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.