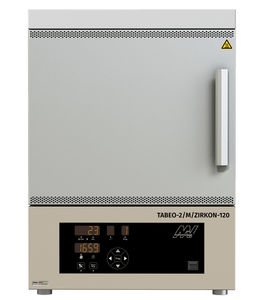

Sintering furnace TABEO-1/M/ZIRKON-100for dental laboratorieszirconiahigh-temperature

Add to favorites

Compare this product

Characteristics

- Function

- sintering

- Applications

- for dental laboratories

- Designed for

- zirconia

- Temperature control

- high-temperature

- Temperature range

Max.: 1,650 °C

(3,002 °F)

Description

The TABEO series is ideal for use either to supplement smaller CAD/CAM systems or for extending existing sintering furnaces.

Their respective capacities vary from one sintering tray Ø= 100mm (TABEO-1/M/ZIRKON-100) up to three sintering trays Ø= 120mm (TABEO-2/M/ZIRKON-120). Your sintering program can easily be entered and saved in the program controller which is adapted for the TABEO series. Pre-set service programs support you during the simple maintenance and cleaning of the heating systems.

The heating system with with 4 heating elements made of MoSi2 is designed for conventional long-term sintering. They allow a maximum furnace temperature of 1650°C. The regular execution of pre-set service programs can prevent possible discoloration of restorations and increase the life span of the heating elements and the heating chamber.

High purity molybdenum-disilicide heating elements

9 programs capacity

9 heating stages

Max. heating rate 25°C/min.

Service programs

A - Temperature control*

only in conjunction with test-kit

C-Purge heating chamber

E- Regenerate heating elements

Catalogs

Related Searches

- Heating furnace

- Laboratory furnace

- Benchtop furnace

- 1-door furnace

- Stainless steel furnace

- Drying furnace

- Mihm-Vogt dental laboratory oven

- Stainless steel fume hood

- Exhaust hood

- Mihm-Vogt high-temperature oven

- Muffle furnace

- Zirconia furnace

- Dental laboratory hood

- Heating oven

- Preheating furnace

- High-performance furnace

- Annealing furnace

- Modular fume hood

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.