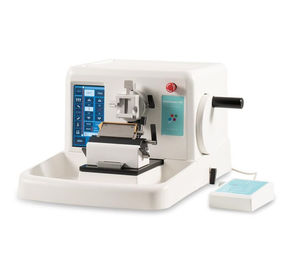

Rotary microtome EasyCUTsemi-automaticfor histology

Add to favorites

Compare this product

Characteristics

- Type

- rotary

- Operation

- semi-automatic

- Applications

- for histology

Description

Electrostatic charges in the cutting process can lead to weaker ribbons that are prone to breakage in subsequent stages.

EasyCUT neutralizes electrostatic charges and thus helps technicians in obtaining a perfect, non-sticky and wrinkle-free ribbon, which is easy to transfer to the water bath.

During cutting, electrostatic charges often make the ribboning difficult, as sections stick to paraffin blocks, forceps, and user’s fingers. The transfer to the water bath is almost impossible, causing delays and ribbons that may break apart. Thanks to EasyCUT’s ionized flow, you can neutralize these charges and obtain perfectly stretched ribbons with neither shattering nor scattering effects.

EasyCUT not only enhances ribbon quality for following stages, but it also plays a pivotal role in improving process efficiency and reducing turnaround time.

With EasyCUT, operators will no longer face all the challenges related to electrostatic charges, thus expediting the cutting process and enhancing productivity.

The operator simply switches on the ionized air flow to instantly remove electrostatic charges from the cutting area. This allows for increased productivity and efficiency, while ensuring sample integrity by eliminating concerns about ribbons sticking to the paraffin block or the operator’s fingers.

EasyCUT is also equipped with LED lights, providing optimal lighting during cutting.

An additional standout feature of this tool is its versatility, as it seamlessly adapts to various microtome setups without requiring any extra space.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Laboratory freezer

- 1-door freezer

- Container

- MILLESTONE sample preparation system

- MILLESTONE automatic sample preparation system

- MILLESTONE laboratory sample preparation system

- Sample box

- MILLESTONE benchtop sample preparation system

- Manual defrost freezer

- Electric freezer

- Stainless steel freezer

- Transport container

- Hospital freezer

- Storage sample box

- Sample container with cap

- MILLESTONE tissue processor

- Vaccine freezer

- Transport sample box

- Liquid handling sample processor

- MILLESTONE histology sample preparation system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.