Thermal transfer printer TTObarcode labelmonochromemultipurpose

Add to favorites

Compare this product

Characteristics

- Printing technology

- thermal transfer

- Printing media

- barcode label

- Other characteristics

- monochrome, multipurpose

Description

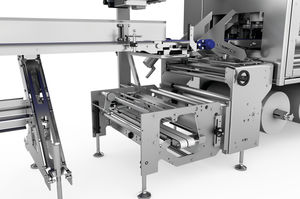

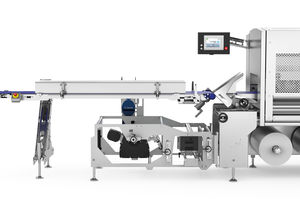

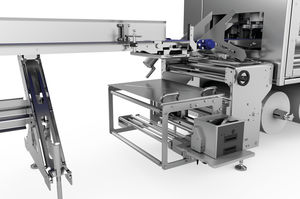

When it comes to increasing efficiency and cost-effectiveness, flexibility and speed are indispensable. What also makes your machine cost-effective? This complete integration into existing MULTIVAC labelling systems and direct web printers, as well as being centrally controlled from one HMI. The automatic loading of the print layouts via the recipe ensures the correct print data is used, and this in turn ensures that the print result is printed. We accompany you throughout the entire lifespan of your line, and we will be at your side with advice and help, and ensure that your products shine with a brilliant print image at the point of sale.

Effortless operation utilizing a graphic user interface

Hygiene design

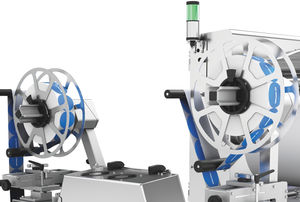

Quick ribbon change

Automatic loading of print layouts

Minimal downtime

Long ribbon length

Low operating costs

MULTIVAC TTO printers are compatible with MULTIVAC labelling and marking systems from HMI 2/3 onwards, and they are suitable for printing on labels, films and trays.

Thermal transfer printing is a digital printing process, in which individual elements of a thermal printhead heat up. This causes the pigment of the thermal transfer ribbon, which is coated with synthetic resin / wax, to melt and be transferred to a label or a packaging film.

Thermal transfer printers achieve a resolution of up to 300 dpi and, in addition to texts and variable data, they can also print barcodes, logos and graphics of the highest quality.

Catalogs

No catalogs are available for this product.

See all of MULTIVAC‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.