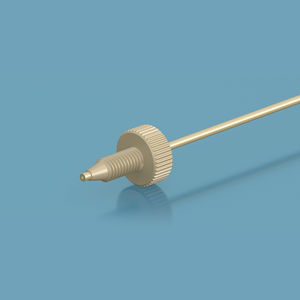

Medical device fitting WF09B

Add to favorites

Compare this product

Characteristics

- Applications

- for medical devices

Description

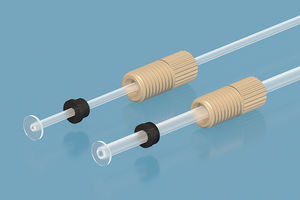

PEEK Flangeless Fittings come with PEEK flangeless nut and ETFE ferrule for your convenience. Flangeless fittings are excellent replacements for flanged fittings, they are dependable, easy to use and easy to replace.

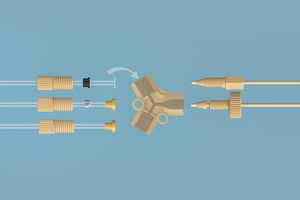

PEEK Super Flangeless Fittings eliminates loosening of fittings due to tubing twist and holds tight even through vibration and increase the reusability with the help of 316 SST sleeves.

PEEK Flangeless Fittings Features at-a-Glance

PEEK nuts featured with high mechanical strength, solvent resistance (except strong sulphuric acid and strong nitric acid), high temperature resistance, wear resistance with its high friction coefficient, impact resistance Yellow Tefzel (ETFE) Ferrules are excellent for connecting most rigid or semi-rigid tubes, including tubing manufactured from fluoropolymers (FEP, PFA, ETFE, ECTFE, etc.), PEEK. It offers superior chemical resistance. It has a 1/4-28 Flat -Bottom port configuration and is for 1.6/2.0/2.5/3.0/3.175mm OD Tubing.

Long-time operation temperature from - 100℃ to + 250℃

Frequent disassembly supported

Suit for mesolow liquid chromatography, gene detection, high-end bioanalysis

Application Note (PEEK Flangeless Fittings)

Step 1. Slide the PEEK nut, followed by the ETFE ferrule, at least 3/16"(4.7625mm) from the end of clean cut tubing

Step 2. Insert the assembly into the receiving port, pushing the tubing into the port until it bottoms out

Step 3. Finger tighten the fittings into the port until snug

Step 4. After several uses (especially at high pressure) the ferrules should be replaced

VIDEO

Catalogs

No catalogs are available for this product.

See all of NANJING RUNZE FLUID CONTROL EQUIPMENT CO., LTD.‘s catalogsOther NANJING RUNZE FLUID CONTROL EQUIPMENT CO., LTD. products

PEEK Fittings

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.