- Laboratory

- Medical research

- Automatic patch-clamp system

- NeoBiosystems, Inc.

- Products

- Catalogs

- News & Trends

- Exhibitions

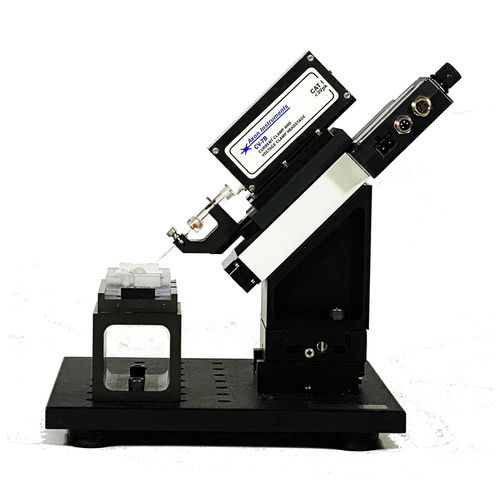

Automated patch-clamp system PatchMAXfor research

Add to favorites

Compare this product

Characteristics

- Type

- automated

- Other characteristics

- for research

Description

The PatchMAX 100A is an automated patch clamping system. Armed with precisely controlled motors, data acquisition board with BNC interface control box, software, and a specially designed perfusion chamber, the PatchMAX 100A Automated Patch Clamp System brings the electrodes to touch the cell membrane by resistance feedback. People thus can do patch clamp experiment without the need for a microscope. When used with the ez-gSEAL Pressure Controller, it makes seals automatically. The system significantly lowers equipment cost and saves lab space. This system relieves researchers from the most labor-intensive part of these experiments and significantly increases productivity. It can be upgraded to a ChannelMAX 100A system, which can be used for both patch clamp and two-electrode voltage clamp.

Key Features

Incredibly small footprint

This patent-pending design has an 8" x 8" footprint; it is the smallest multi-function patch clamp system available. The automated patch clamping system replaces the microscope and the manipulator in the traditional rig. Complete with one automated manipulator, a manual XY stage, a data acquisition board & control system, and a perfusion chamber with the platform, this system can automatically guide electrode to make a seal on oocytes, suspended cells and cells on cover slips.

Automatic membrane detection

The specially designed perfusion chamber guarantees that when oocyte or cells are dropped into the chamber, it always reaches the known position. The tip of the pipette can reach this position with an accuracy of 0.05 mm, assuming the tip of the pipette is perfectly concentric.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.