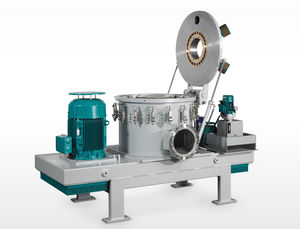

Disc mill MasterRefinerlaboratorycontinuous

Add to favorites

Compare this product

Characteristics

- Technology

- disc

- Applications

- laboratory

- Other characteristics

- continuous

Description

New Standards regarding Power and Flexibility

The horizontal disk mills type MasterRefiner are improved, continuous working laboratory and production machines for wide variety of food and confectionery applications.

The disk agitator shaft activates the grinding media with high intensity through the entire grinding chamber. Highly efficient separation devices that are adapted to your application are available for separation of product and grinding media. This ensures that the mill is reliably operated with high viscous products as well. Depending on the product-specific requirements, the machine can be designed in different materials (e.g. NElast, rubber, ceramics, chilled casting, special steel).

Technique

Highest product quality at exact reproducibility

Narrow grain spectrum down to the sub-micron area

Flexible work with short preparation times

Easy handling

Continuous grinding process with high energy density

Grinding chamber designs adapted to your product

Abrasion-proof wear parts of different materials

Use of grinding media from approx. 0.5 to 5 mm

Classifying separation system for all types of smallest grinding media

High productivity at lowest space requirement

VIDEO

Catalogs

No catalogs are available for this product.

See all of Netzsch‘s catalogsRelated Searches

- Agitator

- Benchtop stirrer

- Digital stirrer

- Blender

- Laboratory grinder

- Industrial mixer

- Pharmaceutical industry grinder

- Benchtop homogenizer

- Electronic homogenizer

- Blender for the pharmaceutical industry

- Rotor grinder

- Analog blender

- Compact mixer

- Mill for the food industry

- Continuous crusher

- Impact mill

- Homogenizer for the pharmaceutical industry

- Disc mill

- Mechanical mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.