- Dental

- Dental practice

- Zirconia dental bridge

- NEW ANCORVIS S.r.l

PMMA dental bridge ceramiczirconiaposterior teeth

Add to favorites

Compare this product

Characteristics

- Material

- ceramic, zirconia, PMMA

- Tooth type

- posterior teeth

Description

Our production workflow, with guarantees of predictability and repeatability, makes these processes easy to use and accessible to everyone.

Key indications: Screw-retained prostheses on implants

Workflow: Digital

Warranty: 10 years

Production: 3-6 days (based on the type of request)

Efficiency

The complex structures are our hallmark in which we continuously invest resources, know-how and technology, in an ever-evolving process of improvement and optimisation

Flexibility

We make these structures on all the implant platforms on the market, both for direct screw- and cement-retention

Additional services

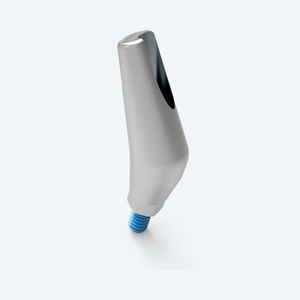

Angled screw channel

Threaded hole

Specific prosthetic components:

Screws

Specific screws for angled hole, Link In System and V4 System cement-retained connectors

Converters for Sly System Line zirconia screw-retained technique

MUA and MUA Slim Fit-type connectors

Quality

All the products we produce undergo systematic checks both during the production process and at the end of the process. The use of regularly calibrated, checked and well-maintained instrumentation guarantees the maximum accuracy of these checks. The end-of-process activities also include a cleaning stage that significantly reduces any processing residues on the pieces produced

Catalogs

No catalogs are available for this product.

See all of NEW ANCORVIS S.r.l‘s catalogsRelated Searches

- Implant abutment

- Titanium implant abutment

- Straight implant abutment

- Internal implant abutment

- Hexagonal implant abutment

- Screw implant abutment

- Angulated implant abutment

- Internal hexagon implant abutment

- CAD/CAM implant abutment

- MUA implant abutment

- Dental prosthesis

- Zirconium implant abutment

- Anterior teeth dental prosthesis

- PMMA dental prosthesis

- Dental bridge

- Surgical guide

- Dental surgical guide

- Ceramic dental bridge

- Posterior teeth dental bridge

- Dental implantology surgical guide

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.